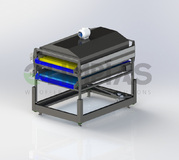

Washing-Brushing Unit

The Brushing/Washing machine has been designed and manufactured to be a part of a more complex processing line for fruit cleaning. It consists of rotating cylindrical hydrophilic brushes for product cleaning and brushing. The number, size, and material for the brushes and sponges depend on the product type and the customer’s specifications. In case product polishing and/or waxing is needed, then the brushes are made of natural horse hair. The rotation speed of the brushes is adjusted by a suitable inverter.

The products enter at the beginning of the machine where they are washed/brushed/dried. This is done in the washing section, where the sprinkler system (water, foam, or other disinfectant, depending on the product processed) works with the brushing system underneath it. In the draining system, the rotating sponges in collaboration with the turbines, drain the processed product. The sponges are squeezed by a straining system located underneath them. Under the upper level, the drainage system, consisting of two tanks, drains the excess water and objects.

After processing, they exit the machine and are transported for further processing on the line.

The machine frame is made of plain steel, while the parts that come in contact with the fruit are made of stainless steel.

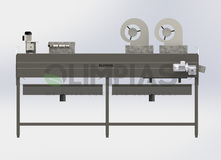

Washing-Brushing Unit with By-Pass

The Brushing/Washing Bypass machine has been designed and manufactured to be a part of a more complex processing line for fruit cleaning. It consists of rotating cylindrical hydrophilic brushes for product cleaning and brushing. The number, size and material for the brushes and sponges depends on the product type and customer’s specifications. In case product polishing and/or waxing is needed, then the brushes are made of natural horse hair. The rotation speed of the brushes is adjusted by a suitable inverter.

It is essentially made up of two units:

- The brushing/washing unit.

- The bypass unit.

Which are situated on top of each other. This is done so that the user is able to choose, which of their products need to be processed and which do not.

The machine has two entries and two exits. If the products are to be processed, they go through the upper level where they are washed/brushed/dried. This is done in the washing section, where the sprinkler system (water, foam or other disinfectant, depending on the product processed) works with the brushing system underneath it. In the draining system, the rotating sponges in collaboration with the turbines, drain the processed product. The sponges are squeezed by a straining system located underneath them. Under the upper level, the drainage system, consisting of two tanks, drains the excess water and objects.

If processing is not required, the conveyor belt rises to a similar height through a chain & gear system and the products pass through it to continue their course in the processing line.

The machine frame is made of plain steel, while the parts which come in contact with the fruit are made of stainless steel.

Brushing-Polishing Unit

The Brushing/Polishing Bypass has been designed and manufactured to be a part of a more complex processing line for fruit cleaning. It consists of rotating cylindrical hydrophilic brushes for product cleaning and brushing. The number, size and material for the brushes and sponges depends on the product type and customer’s specifications. For product polishing/waxing the brushes are made of natural horse hair. The rotation speed of the brushes is adjusted by a suitable inverter.

The products enter the machine through the feeding area, after which they are subjected to polishing/brushing by a brushing system.

The machine frame is made of plain steel, while the parts which come in contact with the fruit are made of stainless steel. The stands are height adjustable.

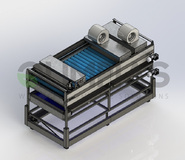

Brushing-Polishing Unit with By-Pass

The Brushing/Polishing Bypass machine has been designed and manufactured to be a part of a more complex processing line for fruit cleaning. It consists of rotating cylindrical hydrophilic brushes for product cleaning and brushing. The number, size and material for the brushes and sponges depends on the product type and customer’s specifications. For product polishing/waxing the brushes are made of natural horse hair. The rotation speed of the brushes is adjusted by a suitable inverter.

It is essentially made up of two units:

- The brushing/polishing unit

- The bypass unit,

Which are situated on top of each other. This is done so that the user is able to choose, which of their products need to be processed and which do not.

The machine has two entries and two exits. If the products are to be processed, they go through the upper level where they are polished/brushed.

If processing is not required, the conveyor belt rises to a similar height through a chain system and the products pass through it to continue their course in the processing line.

The machine frame is made of plain steel, while the parts which come in contact with the fruit are made of stainless steel.