The main purpose of the graders/sizers is to classify products mainly according to their size. They can be divided into two main types, according to their principle of operation (mechanical or electronic).

1-Mechanical sizers work mainly through mechanical calibration. The configuration of these sizers is linear, while classification is limited to product sizing.

2-Electronic graders can be equipped with multiple electronic systems which, in addition to size classification, can also offer the ability to sort according to weight, color and quality. The configuration of the graders varies depending on the processed product and the required production volume. Graders that are configured specifically for some products, such as cucumber, cherry and watermelon are also included in this category.

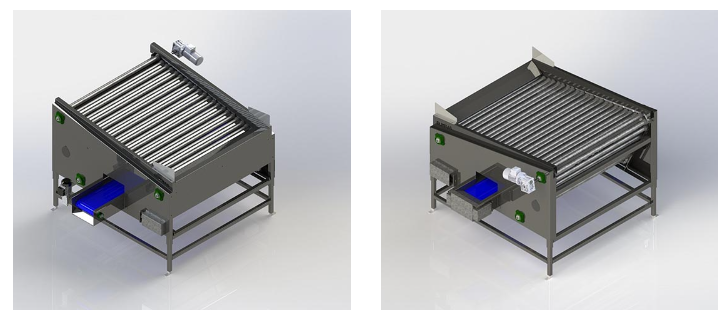

Construction data

- The frame of the machine, is made of sheet metal and beams, while the cylinders which come in contact with the products are galvanized.

- Movement of the cylinders is actuated by a chain system located on each side. The chain system is held in place by a guide on each side. Power transmission is done by a suitable engine and inverter.

- The adjustment of the cylinder opening is achieved through manual handles located on the side of the machine.

- The conveyor belt which is used to export smaller diameter products is made of PVC, and is powered by a second motor included in the machine.

Applies to

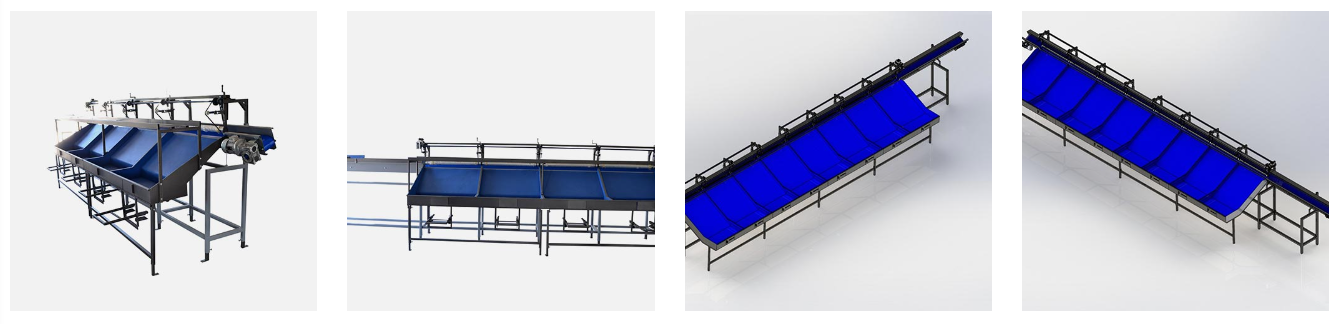

Side Emptying Mechanical Sizer

The purpose of the machine is to sort the fruits based on their size. The machine is mainly used for the sorting of citrus fruits, being able to process even fruits with leaves. The machine consists of an inclined transportation belt carrying the fruits, and independent rotating drums (rollers). Each drum is calibrated through a calibration wheel attached on it, increasing or decreasing the distance between the drum and the belt. Depending on the calibration of each drum, the fruits are forwarded to each fruit tray as long as their diameter allows them to pass through the opening that has been created.

The number of the packing stations varies depending on customer's needs. Each station contains a fruit tray measuring 1200 mm x 1000 mm, lined with elastic material to avoid any damage of the fruits while, above the unit’s entire length, a shelf is installed where the empty boxes are placed. Also, to make it easier for the operator to fill the boxes, a working bench is installed under the fruit trays, where the operator can place the empty box for packaging.

Applies to