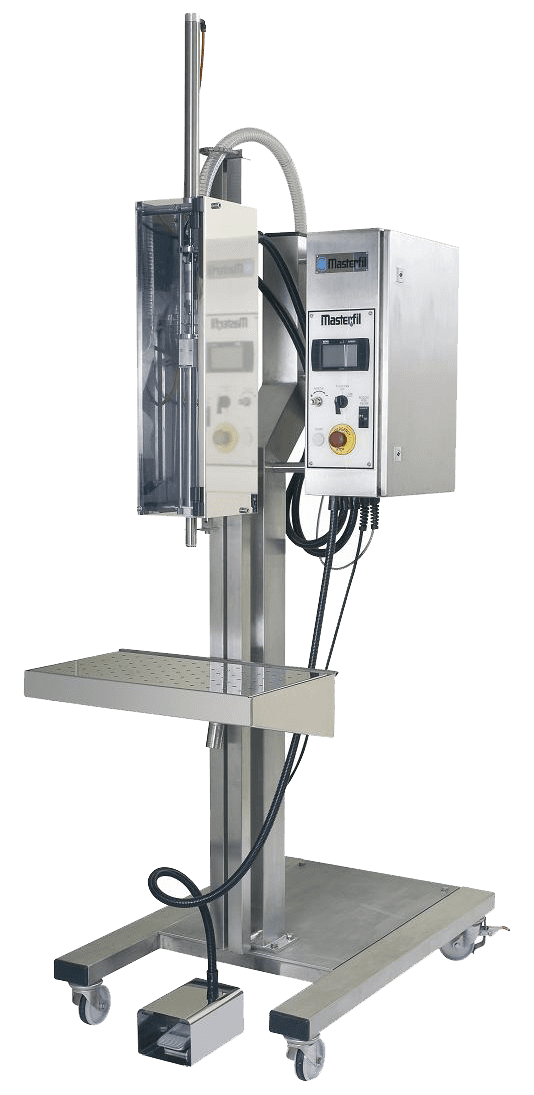

Faster Filling, Higher ROI .. Reduces Waste, Increases Profitability .. Up to 720 Containers per Hour

Product Specification:

- Fill volumes from 500ml to 5L.

- Exceptional accuracy of up to ±0.2% reduces waste.

- Durable and robust, to endure the harshest of environments.

- Versatile; nozzles are adjustable to fill foaming and non-foaming products with variable speed filling capacity.

- No pistons; quick product and container changeover to minimise production downtime.

- Suitable for low to high viscosity liquids.

- Hygienic 316L stainless steel / PTFE contact parts.

- Can be specified with one or two filling heads.

Key Features

• Able to fill a wide range of container sizes

• Accurate to ±0.2%

• Quick and easy to clean

• 316L stainless steel / PTFE / Viton contact parts

• Can utilise either electro-magnetic or Coriolis technology

• Nozzles can be static, or set to dive and rise whilst filling or fill into neck, depending on product type

• Optimum output is achieved by key pad controls and with no pistons to clean, changeover time is reduced

• Minimum down time between liquid and container changeovers.

• 1 or 2 filling heads

• Non-drip cut-off nozzle

Please Note: This machine can be made ATEX compliant for flammable products.