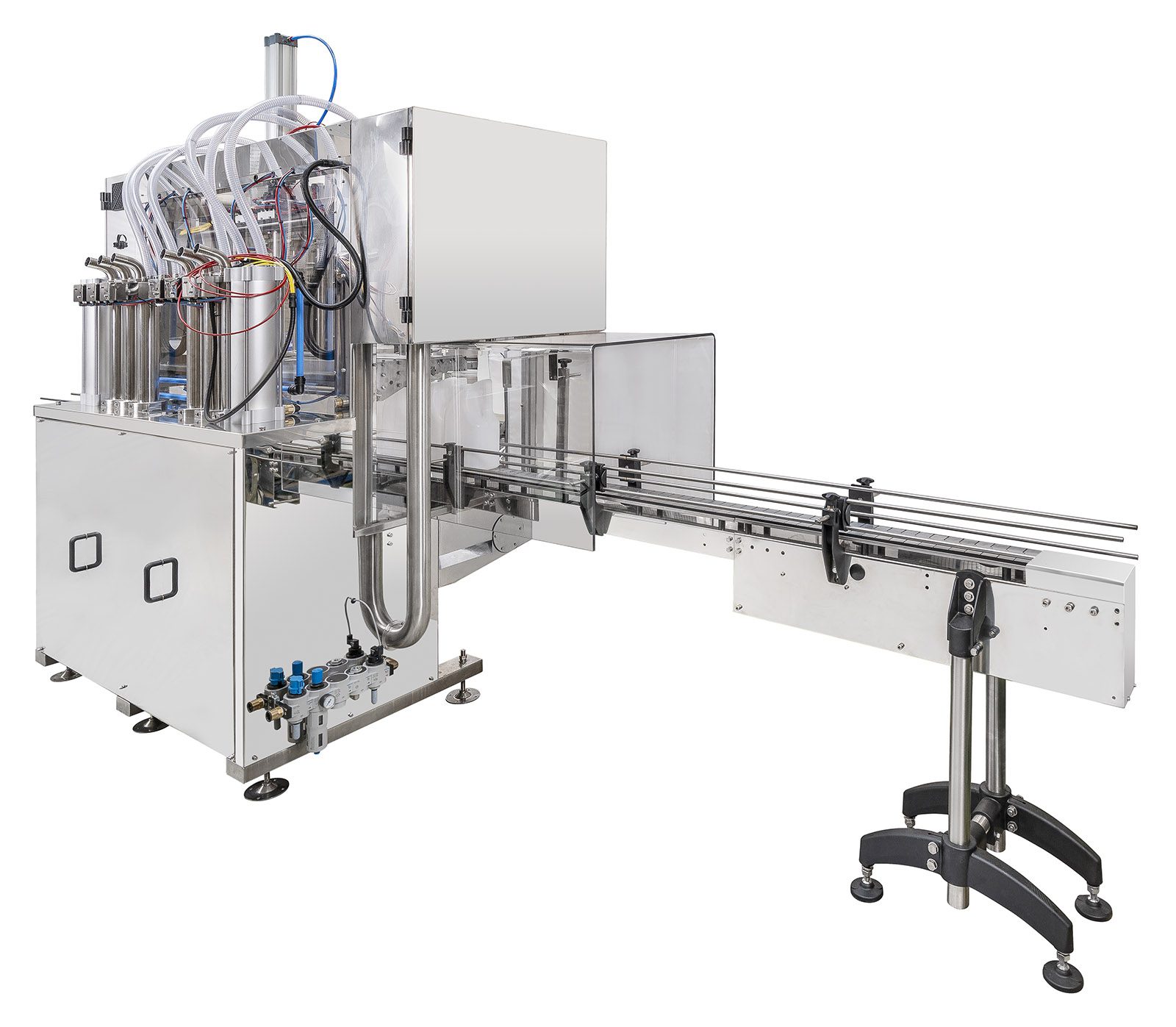

Faster Filling, Higher ROI .. Reduces Waste, Increases Profitability .. Up to 4,500 Containers per Hour

Product Specification:

- Fill volumes from 250ml to 30L.

- Exceptional accuracy of up to ±0.2% reduces waste.

- A choice of between 2 - 12 filling heads.

- Add extra heads to meet increased output requirements.

- Durable and robust, to endure the harshest environments.

- Versatile; nozzles can be programmed to dive and rise whilst filling, fill into neck or remain above neck.

- ‘No container, no fill’ sensing reduces waste and saves money.

- Storing multiple filling profiles increases efficiency on line throughputs.

- Easy recall of container fill profiles de-skills the machine operation.

- Suitable for low to high viscosity liquids.

- Hygienic 316L stainless steel / PTFE contact parts.

Key Features

• PLC controlled, with recipe-driven HMI

• Single or double action product cylinders of 1, 3, 5 or 6 litre capacity

• Variable fill speeds can be used during a filling cycle

• Totally enclosed 304 stainless steel and PVC filling area

• 316L stainless steel / PTFE / Viton contact parts

• Nozzles can be static, or programmed to dive and rise whilst filling or fill into neck, depending on product type

• Fully automatic container handling system includes ‘no container, no fill’ sensing

• Quick change of volume with digital readout

• Flushing circuit for in-place cleaning (optional).

• ATEX compliant (optional)

• Choice of pneumatic or servo operation

• Pharmaceutical grade stainless steel box section conveyor with variable speed control

Please Note: This machine can be made ATEX compliant for flammable products.