The purpose of the feeding machines is the smooth and safe feeding of

products to the machines of the production line. Feeding can be done either

automatically or manually.

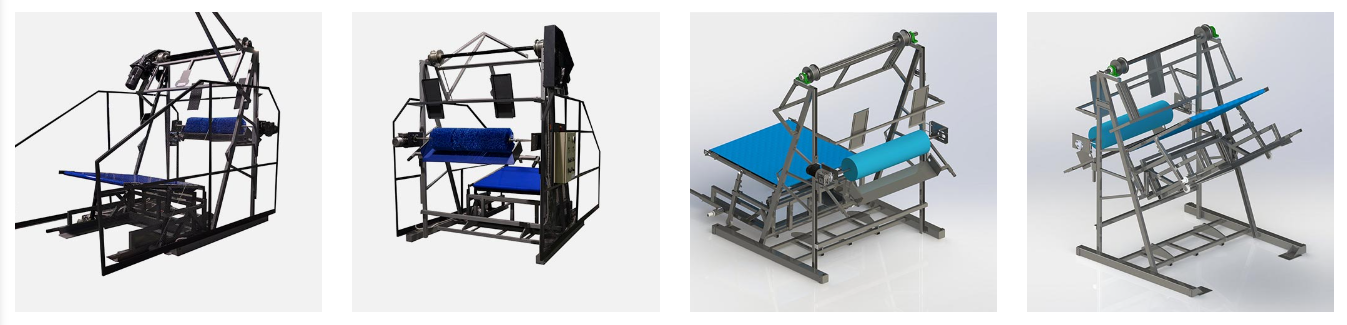

Automatic Bins Dumper

ontaining sensitive products such as apples, pears, kiwi, peaches, etc. The Bins/Pallet Box dumper ensures smooth supply with continuous and controlled flow of the production line. An additional advantage of the machine is that it can handle all the usual box sizes. The machine consists of two parts, (the fixed and the moving part). The moving part consists of a suitable belt on which the pallet box is placed. The belt helps the pallet box to get into the correct position on the base. For this purpose, a suitable photocell system and/ or timer has been fitted to control the smooth filling of the base with the pallet box. After the pallet has reached the proper position it starts the rollover. The entire rollover is done using a cable system. On the fixed base an additional photocell system is mounted to check if the pallet box has reached the correct rollover position in order to stop the movement. At that height there is a cylindrical brush system which helps the products come out smoothly from the pallet box. The machine includes an electrical board that contains all control and management automation. This ensures the correct and smooth operation of the process. The capacity of the system depends on the size of the pallet box and can reach up to 30 BINS per hour.

Applies to