The main purpose of the graders/sizers is to classify products mainly according to their size. They can be divided into two main types, according to their principle of operation (mechanical or electronic).

1-Mechanical sizers work mainly through mechanical calibration. The configuration of these sizers is linear, while classification is limited to product sizing.

2-Electronic graders can be equipped with multiple electronic systems which, in addition to size classification, can also offer the ability to sort according to weight, color and quality. The configuration of the graders varies depending on the processed product and the required production volume. Graders that are configured specifically for some products, such as cucumber, cherry and watermelon are also included in this category.

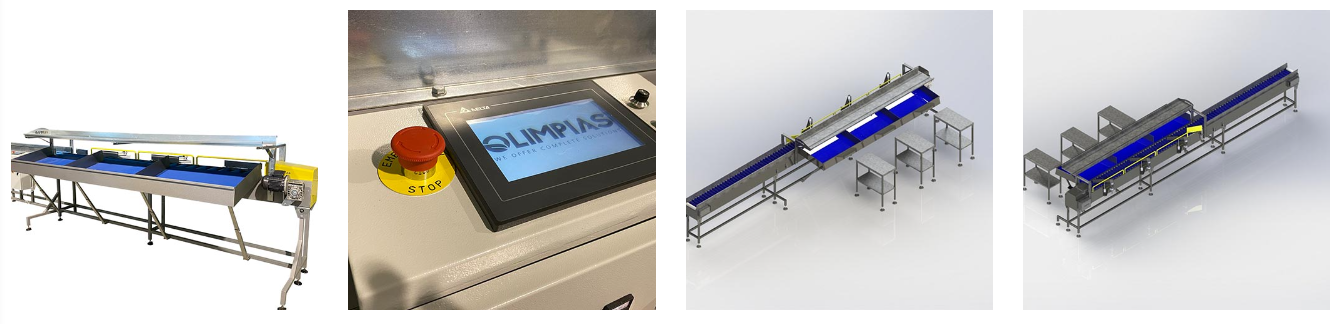

The machine consists of:

- Main body with power unit.

- Weighing device.

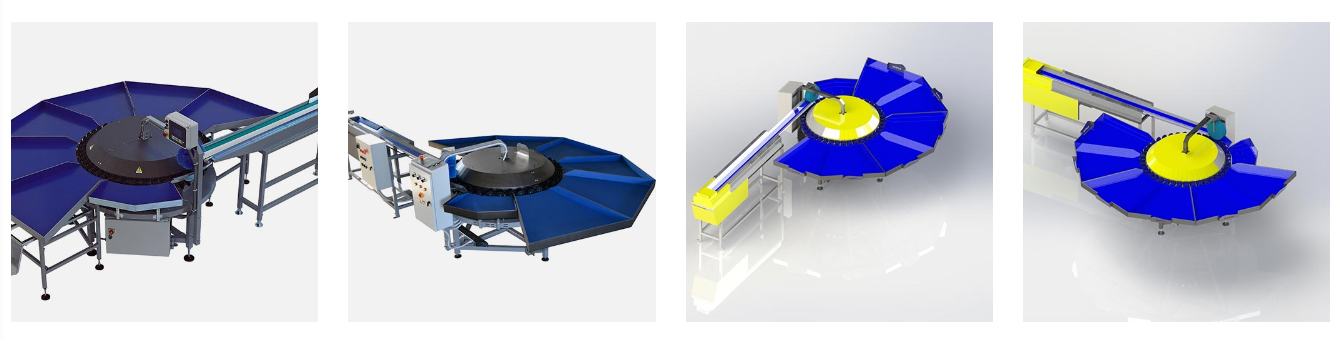

- Product transportation system (rotating disk – fruit carriers).

- Fruit trays for the sorted fruits.

- Electronic sorting system by weight.

- Electrical panel with control display.

The Mini-CC can work as:

- An electronic sorter of continuous operation.

- A sampling machine.

- A semi-automatic batching - packaging machine with the addition of box filling and bagging machines.

Processing cycle:

- The fruits are transferred to the machine through its infeed V-belt.

- The V-belt places the incoming fruits in a row one after the other, ensuring the proper and continuous flow of products to the sorter.

- On entry point, the products are placed in the cups passing through a soft brush system ensuring the safe placing of the fruits without damage.

- The cups carrying the fruits pass over the weighing system (load cell) so the electronic system can receive the weight of every fruit and sort it according to the program the operator has set.

- The ejection system on every exit gently tilts the cups so the fruits can exit the machine to the proper fruit tray for packaging.

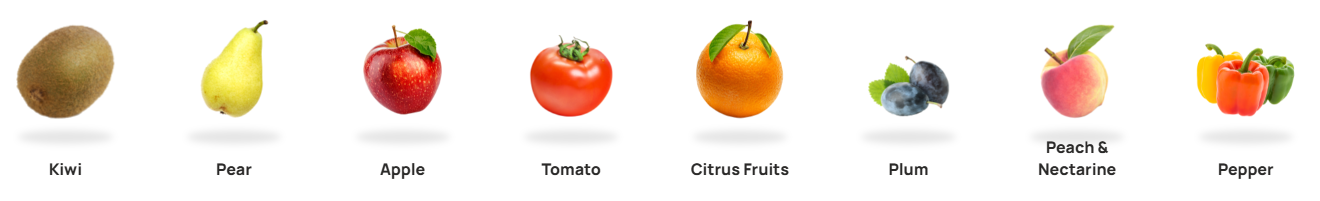

Applies to

Electronic Grader (OL-1LES)

The machine consists of:

- Front side.

- Weighing sorting unit (colour – diameter sorting unit with the use of a camera - optional).

- Back side (including power unit).

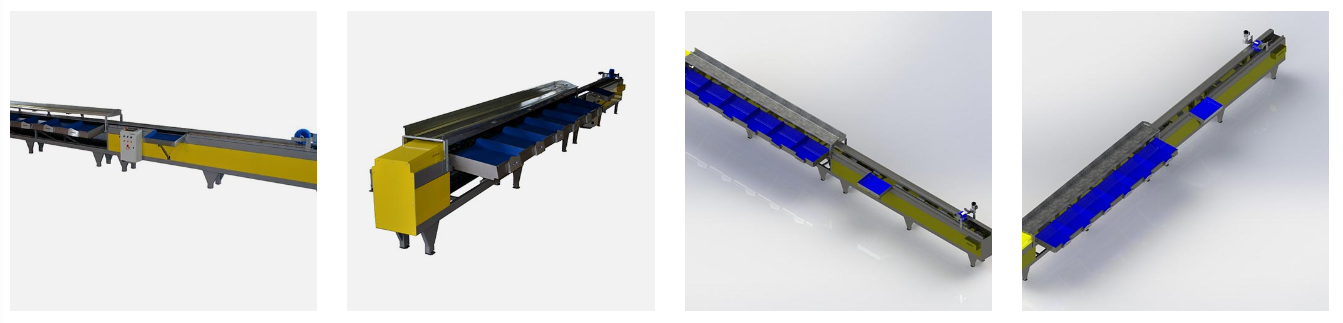

- Product transferring system (cups).

- Fruit trays (the number of fruit trays may vary depending on the processing needs).

Processing cycle:

- The fruits are transferred to the machine through its infeed V-belt.

- The V-belt places the incoming fruits in a row one after the other, ensuring the proper and continuous flow of products to the sorter.

- On entry point, the products are placed in the cups passing through a soft brush system ensuring the safe placing of the fruits without damage.

- The cups carrying the fruits pass over the weighing system (load cell) so the electronic system can receive the weight of every fruit and sort it according to the program the operator has set.

- The ejection system on every exit gently tilts the cups so the fruits can exit the machine to the proper fruit tray for packaging.

Electronic Grader (OL-2LES-FT)

The machine consists of:

- Front side.

- Weighing sorting unit (colour – diameter sorting unit with the use of a camera - optional).

- Back side (including power unit).

- Product transferring system (cups).

- Fruit trays (the number of fruit trays may vary depending on the processing needs).

- Packing station (optional).

Processing cycle:

- The fruits are transferred to the machine through its infeed V-belt.

- The V-belt places the incoming fruits in a row one after the other, ensuring the proper and continuous flow of products to the sorter.

- On entry point, the products are placed in the cups passing through a soft brush system ensuring the safe placing of the fruits without damage.

- The two lines of cups carrying the fruits pass over the weighing system (load cell) so the electronic system can receive the weight of every fruit and sort it according to the program the operator has set.

- The ejection system on every exit gently tilts the cups so the fruits can exit the machine to the proper fruit tray for packaging.

The Two Machines are Applies to

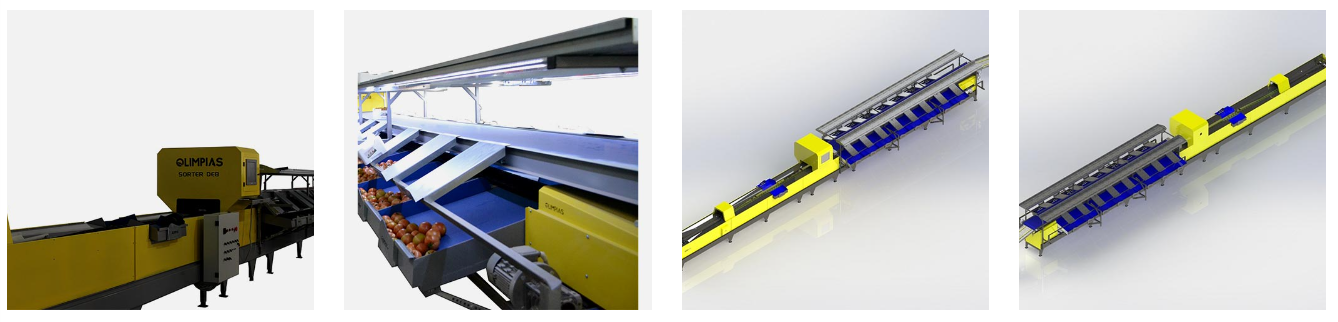

Electronic Grader (OL-2LES-CB)

The machine consists of:

- Front side.

- Weighing sorting unit (colour – diameter sorting unit with the use of a camera - optional).

- Back side (including power unit).

- Product transferring system (cups).

- Fruit exit belt system (the number of belts may vary depending on the processing needs).

Processing cycle:

- The fruits are transferred to the machine through its infeed V-belt.

- The V-belt places the incoming fruits in a row one after the other, ensuring the proper and continuous flow of products to the sorter.

- On entry point, the products are placed on the two lines of cups which pass through a soft brush system ensuring the safe placing of the fruits without damage.

- The cups carrying the fruits pass over the weighing system (load cell) so the electronic system can receive the weight of every fruit and sort it according to the program the operator has set.

- The ejection system on every exit, gently tilts the cups so the fruits can exit the machine to the proper exit belt for packaging.

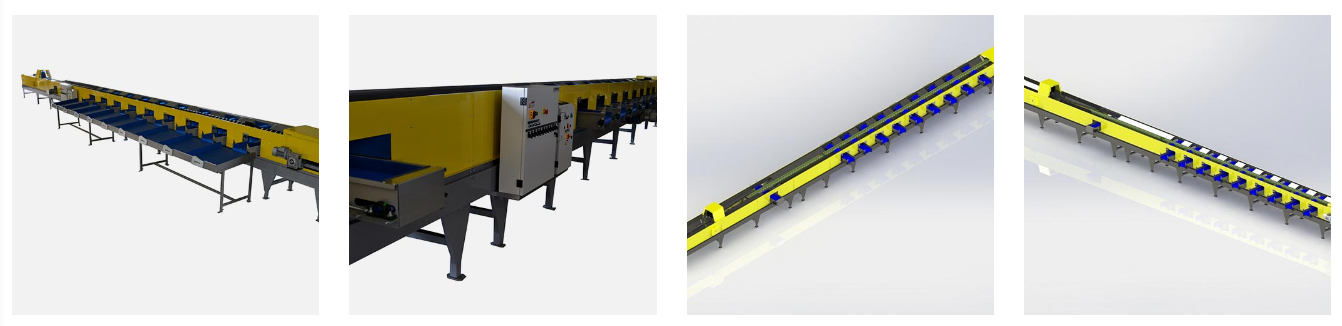

Electronic Grader (OL-4LES-CB)

The machine consists of:

- Front side.

- Weighing sorting unit (colour – diameter sorting unit with the use of a camera - optional).

- Back side (including power unit).

- Product transferring system (cups).

- Fruit exit belt system (the number of belts may vary depending on the processing needs).

Processing cycle:

- The fruits are transferred to the machine through its infeed V-belt.

- The V-belt places the incoming fruits in a row one after the other, ensuring the proper and continuous flow of products to the sorter.

- On entry point, the products are placed in the cups passing through a soft brush system ensuring the safe placing of the fruits without damage.

- The cups carrying the fruits pass over the weighing system (load cell) so the electronic system can receive the weight of every fruit and sort it according to the program the operator has set.

- On every exit, an ejection system gently tilts the cups so the fruits can exit the machine to the proper fruit exit belt. Their drop is slowed down by a soft brush, in order to nullify possible damage to them.

The Two Machines are Applies to

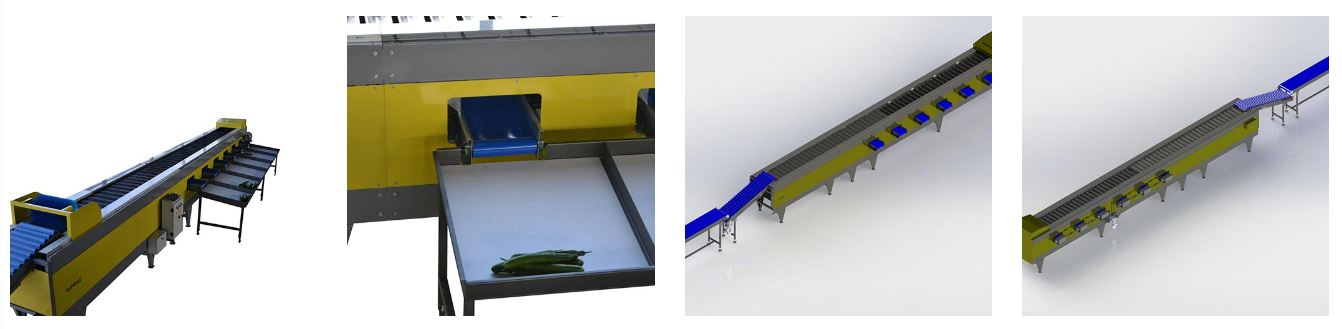

Electronic Grader for Cucumber

The machine consists of:

- Front side.

- Weighing system.

- Back side (including power unit).

- Product transferring system (cups).

- Εxit belt (the number of exit belts may vary depending on the processing needs).

Processing cycle:

- The cucumbers are transferred to the machine through its infeed cleated belt. The cleated belt places them in a row one after the other, ensuring the proper and continuous flow of products to the sorter.

- On entry point, the cucumbers are placed in the cups, which are specially designed for the cucumber shape.

- The cups carrying the fruits pass over the weighing system (load cell) so the electronic system can receive the weight of every cucumber and sort it according to the program the operator has set.

- The ejection system on every exit gently tilts the cups so that the cucumbers can exit the machine to the proper exit belt for packaging.

Applies to

Electronic Grader for Watermelon-Μelon

The machine consists of:

- Front side.

- Weighing system.

- Back side (including power unit).

- Product transferring system (roller system).

- Fruit trays (the number of fruit tray may vary depending on the processing needs).

Processing cycle:

- The watermelons/melons are transferred to the machine through its infeed cleated belt. The cleated belt places them in a row one after the other, ensuring the proper and continuous flow of products to the sorter.

- On entry point, the watermelons/melons are placed on the roller transporting system, which is specially designed for their shape.

- The roller system carrying the fruits passes over the weighing system (load cell) so the electronic system can receive the weight of every watermelon/melon and sort it according to the program the operator has set.

- The ejection system on every exit gently tilts the cups so the fruits can exit the machine to the proper fruit tray for packaging.

Applies to