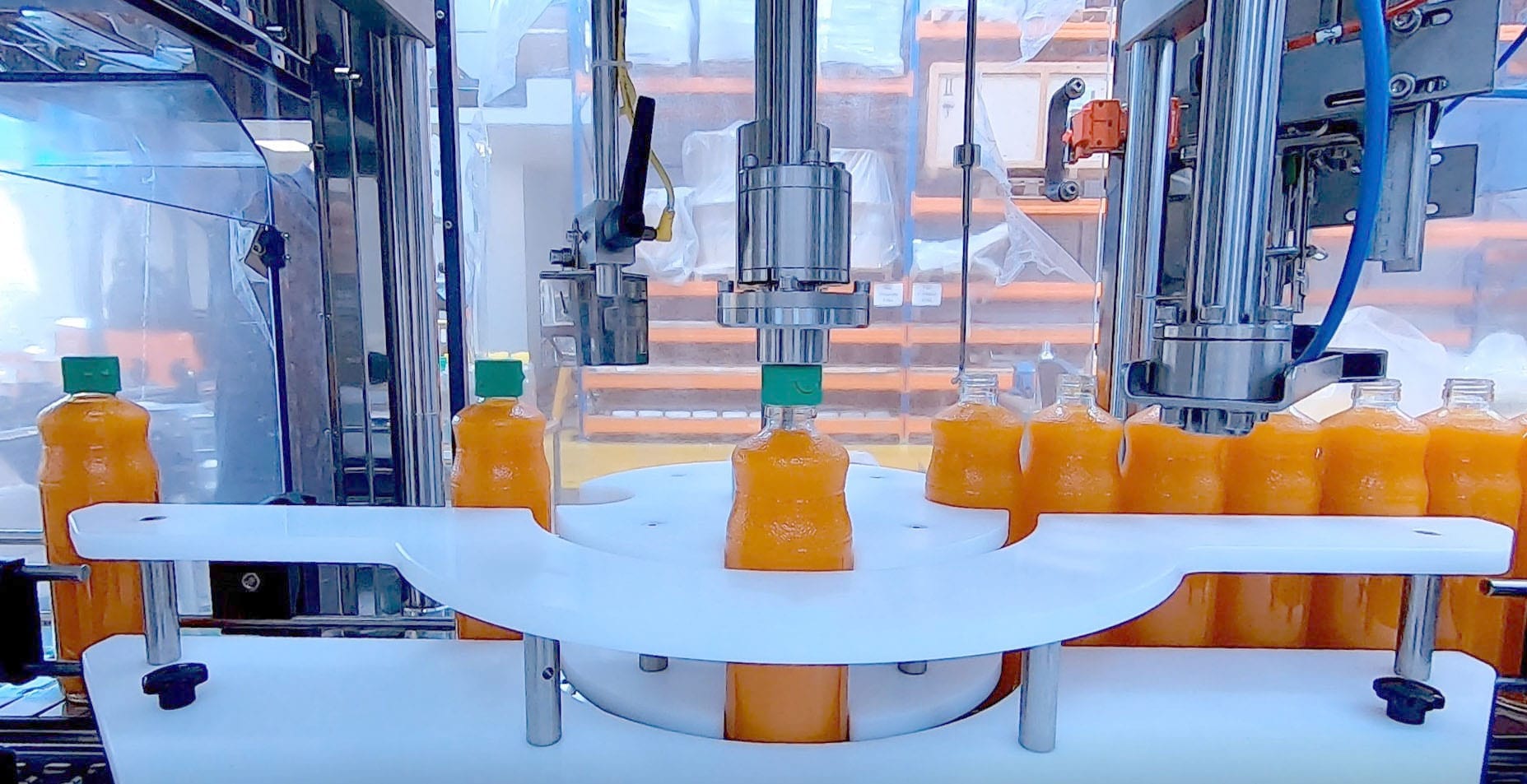

High Efficiency & Throughput .. Reduces Waste, Increases Profitability .. Up to 3,600 Caps per Hour

Product Specification:

- Ideal for cap diameters 20 - 80mm.

- Fast and reliable application of up to 60 caps per minute.

- Robust 304 stainless steel construction.

- Cap track low level detection avoids disrupting production.

- No container, no cap and queue sensing reduces cap waste.

- Easily adjustable variable torque by magnetic clutch.

- Capping zone protected by interlocked guards for operator safety.

- Includes cap feed elevator with pneumatic orientator.

- Can be ATEX compliant for flammable products.

- Suitable for:

- Screw caps

- Press on caps

- Tamper proof caps

- Aerosol overcaps

- Inserts

Key Features and Options

• Easily adjustable variable torque magnetic clutch

• In-line model available for containers up to 25 litres

• ‘No container, no cap’ and queue sensing

• Push button height adjustment

• Cap track low level detection

• 304 grade stainless steel cladding

• Elevator cap feeder/sorter

• Vibratory bowl feeder

• Programmable touch screen HMI controls

• ATEX compliant

• Missing cap detector.

• ‘No foil’ detection and cap reject