Weighing

Electronic Weighing Machine

Drying

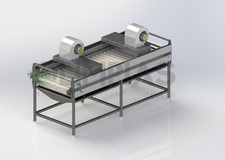

Pre-Dryer

The Pre-Drying Tunnel is a roller conveyor with a hot air generator on top of it. It is ideal for Citrus fruits. Additionally, it can be used for more sensitive products.

- Metal structure that has been properly welded and treated with three layers of polyurethane varnish with internal parts in stainless steel AISI 304.

- Series of aluminum rollers or galvanized.

- Rollers rotation system.

- Hot air generator using one oil (diesel) burner.

- Series of centrifugal fans.

- Air recirculating system.

- Set of proper gear motors (for centrifugal fans).

- Main drive employing proper gear motor and electronic speed variation (Inverter for the roller conveyor).

- Thermostat with temperature indicator for easy temperature setup.

- Control board.

- Combustion chamber made of stainless steel (INOX).

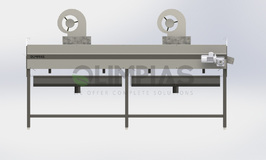

Dryer

The Drying Tunnel is a roller conveyor with a hot air generator on top of it. It is ideal for Citrus fruits. Additionally, it can be used for more sensitive products.

- Metal structure that has been properly welded and treated with three layers of polyurethane varnish with internal parts in stainless steel AISI 304.

- Series of aluminum rollers or galvanized.

- Rollers rotation system.

- Hot air generator using one oil (diesel) burner.

- Series of centrifugal fans.

- Air recirculating system.

- Set of proper gear motors (for centrifugal fans).

- Main drive using proper gear motor and electronic speed variation (Inverter for the roller conveyor).

- Thermostat with temperature indicator for easy temperature setup.

- Control board.

- Combustion chamber made of stainless steel (INOX).

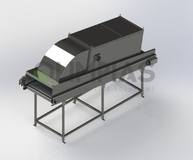

Draining Unit

The draining machine has been designed and manufactured to be a part of a more complex processing line for fruit cleaning. It consists of rotating cylindrical sponges for product straining and drying. The number, size, and material of the sponges depend on the product type and customer’s specifications. The rotational speed of the brushes is adjusted by a suitable inverter.

The products enter the machine through the feeding area, after which they are subjected to drying by a sponge system. The rotational movement of the sponges is also used to transport the products from entry to exit, and the sponges themselves are strained through a rotating roller system located underneath them. A turbine system, installed on the cover of the machine, provides airflow for added product drying.

The machine frame is made of plain steel, while the parts that come in contact with the fruit are made of stainless steel. The stands are height adjustable.