- Details

- Category: Fruits & Vegetables

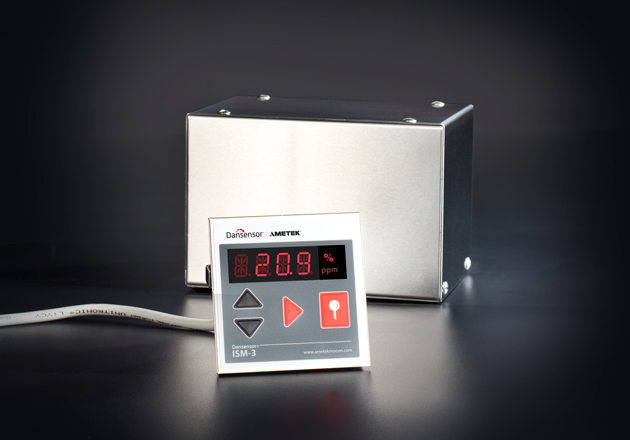

The industrial process analyzer ISM-3 is a digitally controlled analyzer capable of measure inert gases and CO2.

- Great reliability (better than ± 1% of reading)

- Low demand for maintenance

- Large measuring range: 1 ppm – 100 %

- Self-diagnostics system

With its self-diagnostic system and 2 programmable gas alarms, the Dansensor® ISM-3 Oxygen Process Analyzer continuously monitors the oxygen level and alerts the operator if it does not comply with the preset limit. This makes the industrial oxygen monitor highly accurate and very easy to use.

Features of the O2 monitor:

- Two O2 concentration alarms

- Sample gas supply by gas pressure or internal pump

- Different set-up options for adaptation

- 0/4 - 20 mA as standard (optional: 0-10V if specified with the order)

Benefits

- High reliability and accuracy - better than ± 1% of reading

- Low maintenance demand

- Measuring range: 1 ppm - 100% (std. 0-20.9%)

- Self-diagnostics - monitoring of vital parameters with alarm output

Features

- 2 oxygen concentration alarms

- Sample gas supply by gas pressure or internal pump (specific instrument versions)

- Different set-up options for adaptation to the analyzer application

- 0/4 - 20 mA as standard (optional: 0-10V if specified with the order)

- Details

- Category: Fruits & Vegetables

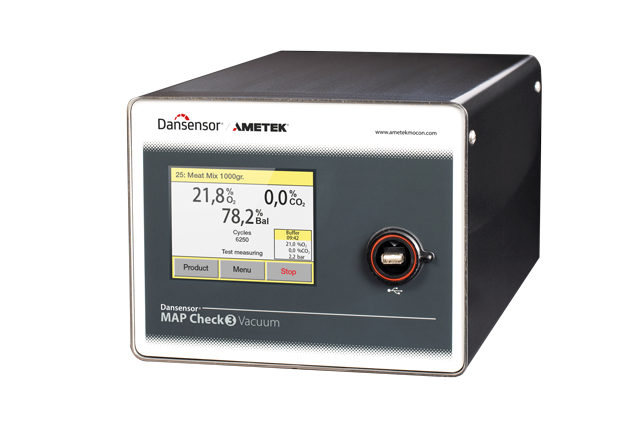

On-line gas analyzer for quality assurance of thermoforming and tray sealing machines.

- Oxygen or combined oxygen and carbon dioxide measurement

- Continuous monitoring and effective control of every packaging cycle

- Automatic production halt in case of exceeded gas limits to avoid recalls or repackaging

- User configurable alarms for low and high gas concentrations

Benefits

- Stops the packaging machine if preset gas limits are exceeded

- Measures every packaging cycle

- Continuous process monitoring of gas content

- Reduces labor and waste costs compared to manual testing

- Avoids recalls/repacking by stopping packaging machine if measurements exceed preset limits

Features

- Oxygen or combined oxygen and carbon dioxide measurement

- Alarms for low or high gas concentrations

- Improved data logging capabilities with USB and Ethernet

- Ability to control the Dansensor MAP Mix Provectus gas mixer

- Delivered with PC software for LAN based data collection

- Optional measurement of buffer tank gas composition and pressure

- User configurable alarms

- Extended remote monitoring and control options with Modbus TCP

- Details

- Category: Fruits & Vegetables

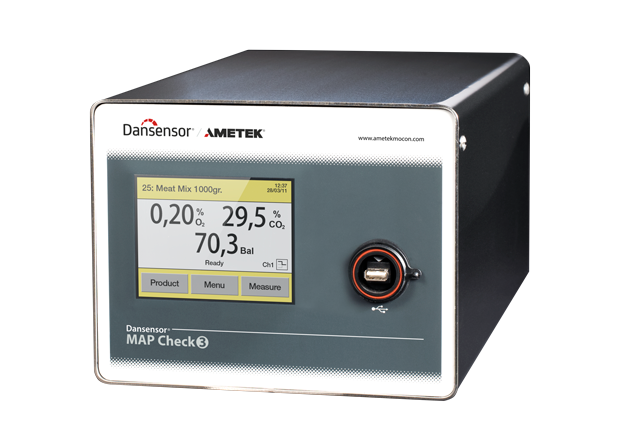

The Dansensor® MAP Check 3 analyzer for flexible gas control of pressurized gases

- Ensures that the correct gas mix is being supplied to your MAP process

- Provide options for Data logging through USB, Ethernet or TCP Modbus

- Works seamlessly with Dansensor® MAP Mix Provectus® gas mixer for ongoing monitoring of gas mixture composition.

The Dansensor MAP Check 3 Pressure allows you to measure pressurized gases directly from a pressurized source like a gas mixer or buffer tank. This pressure gas analyzer can measure both O2 and CO2 as well as check for impurities and measure the balance of gases. With feedback control and high efficiency, the Dansensor MAP Check 3 Pressure is certain to reduce waste and ensure cost savings in Modified Atmosphere Packaging.

Among other benefits, Dansensor MAP Check 3 Pressure:

- Comes with a color touch screen display

- Can automatically stop your MAP process if the wrong gas mix is detected

- Zirconia sensor

- Works with inlet pressures from 2-10 bar (30-145 psi)

Benefits

- Ensures that the right gas mix is supplied to your process

- Logs and displays actual gas mix

- Works with inlet pressures from 2-10 bar (30-145 psi)

- Can stop your process before the wrong gas mix is supplied

Features

- 5” colour touch screen

- Improved data logging capabilities with USB, Ethernet, TCP Modbus

- Ability to remote control the Dansensor MAP Mix Provectus gas mixer

- Details

- Category: Fruits & Vegetables

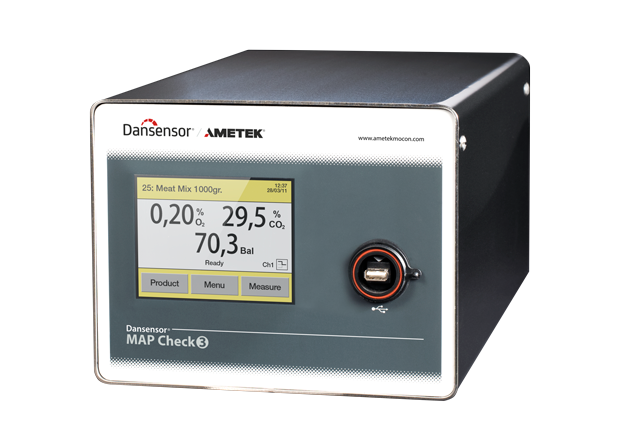

Dansensor® MAP Check 3 continuous gas analyzer is designed to precisely monitor gas content on vertical and horizontal flow packaging machines.

- Major gas savings with optional GasSave function or when paired with Dansensor® MAP Mix Provectus® gas mixer

- On-line Quality Assurance of every package – more efficiently and with reduced labor and waste costs compared to manual testing

- logging and displaying of actual gas consumption with the GasSave function for easy traceability

- automatic stopping of the packaging machine if preset limits are exceeded, helping to avoid recalls and repacking

- Reduced CO2 levels in the work area to protect employees

Benefits

- Enables major gas savings with optional GasSave function or when paired with Dansensor MAP Mix Provectus gas mixer

- Logs and displays actual gas consumption for easy traceability with GasSave function

- Reduces labor and waste costs compared to manual testing

- Avoids recalls/repacking by stopping packaging machines if measurements exceed preset limits

- Reduces work area CO2-levels to protect employees

Features

- 5" color touch screen

- Improved data logging capabilities with USB and Etherrnet

- Ability to control Dansensor MAP Mix Provectus gas mixer

- Delivered with PC software

- Option: 3-channel multiplexer

- Extended remote monitoring and control options with Modbus TCP

- Details

- Category: Fruits & Vegetables

Vacuum leak detection system for flexible, rigid and semi-rigid packages

- Test seal strength and ‘whole package’ integrity

- Automate tests and store parameters for definable, reproducible results

- Performs methylene blue dye test and bubble emission test (ASTM D3078)

- Data capture, storage and export via USB

- Intuitive GUI touchscreen with secure user logins

- IQ/OQ validation documents available

Benefits

- High precision vacuum regulation

- No adjustment required for different package sizes or types

- Clear and concise on-screen test results

- One-touch documentation print-out with external printer

- Easy installation and operation

- Automatically capture and store data

- Test package integrity with blue dye or bubble test

Features

- Touchscreen with GUI for user-friendly operation

- Vacuum generation with vacuum pump or compressed air

- Individual user logins and access levels for security

- Store test parameters for repeatability

- Data capture, storage and export

- USB port for connecting optional barcode scanner, keyboard or printer

- Optional accessories incl. vacuum chambers, vacuum pump unit and barcode scanner

- Multilingual user interface

- Compliant with ASTM D3078

- IQ/OQ validation documents available