Grinders

Today, consumers can enjoy roasted coffee in numerous variations. Coffee grinding is of great importance for the cup quality. Whether instant, filter coffee, espresso, pads or capsules, a grinder has to accommodate a variety of requirements. With over 40 years of experience in coffee grinding, the roll grinders of Neuhaus Neotec represent the current state of the art.

The different grinding degrees from instant to microfine are reached quickly, precisely and reproducibly. Uniform particle size distribution, high throughput, recipe control and wide compacting rates are performance features, just like long service lives and low maintenance costs.

The roll grinders of Neuhaus Neotec cover the entire coffee production spectrum. For optimum fulfilment of every single demand, our grinders are divided into different products:

- LWM - The laboratory grinder

- WMS - Modular grinder series for small to medium capacities

- WMK - Modular grinder series for high and highest capacities

- Neogrind - The special grinder for the highest demands

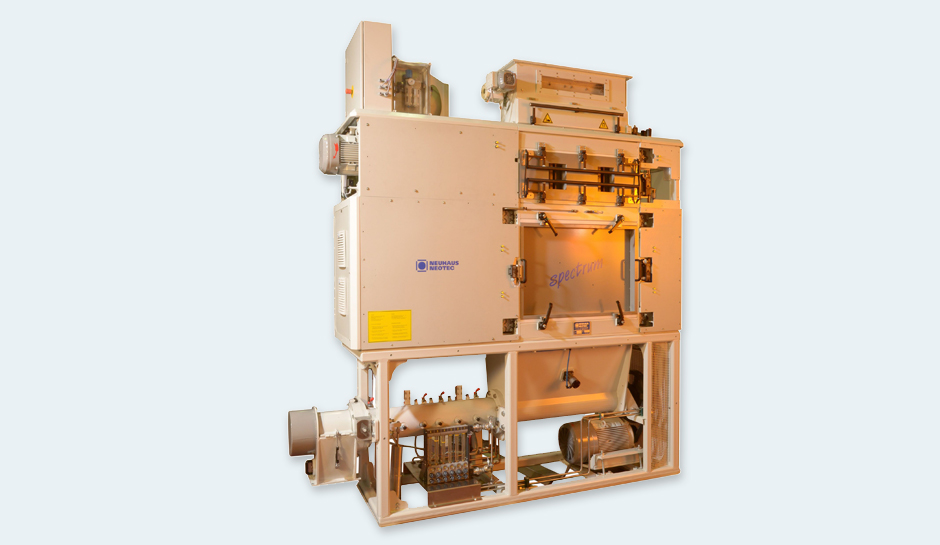

Coffee grinder WMK

WMK Series 250

The WMK 250 is a classic roll grinder with central or sectional drive and timing belt drive as well as compactor. Its advantages are low maintenance, high availability and reproducible and constant grinding degree with uniform particle size distribution.

The WMK 250 is a well-proven machine with maximum capacity of more than 5 tons, depending on the product. Due to the modular design and various capacity options, it can be configured optimally to the individual needs of the customer.

Technical Features

- Multi-stage, gradual grinding

- Central drive for two passages

- Roller drive without shearing forces due to homocinetic cardan shafts

- Spur gear and timing belt drive

- Mixer/compactor for crushing of chaff and increase of the bulk density

- Uniform particle size distribution

- High throughput for espresso, filter coffee and instant coffee grinding

- Magnetic metal separator

Options

- Roller tempering and cooling unit

- Third passage

- Servo-adjustment of the grinding gap

- Gas-tight design

- Bearing temperature monitoring

- Continuous adjustment of the compactor via servomotor

- Vibration sensors

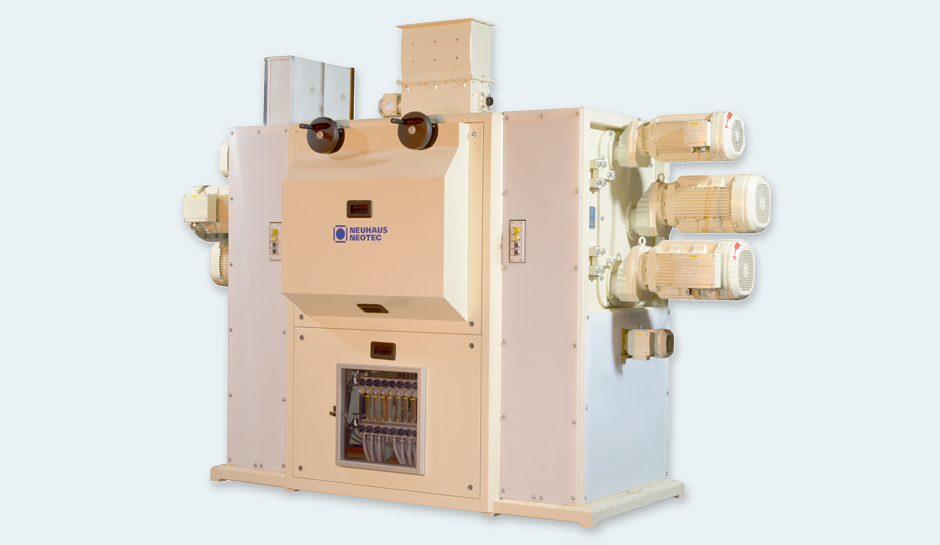

Grinder WMS

For small to medium capacities

The coffee grinders of the series WMS have been designed especially for small to medium capacities. They are available as one, two or three-passage grinder. The grinders have by default a central drive, but optionally also an individual drive as in case of the WMS 43-E.

Low maintenance due to simple roll change, uniform particle size distribution and high throughput for espresso as well as filter and instant grinding characterize the WMS and make it the right choice for every requirement, in particular pad grinding.

Technical Features

- Depending on the design, central drive for the crusher, grinding section and mixer compactor or

- optionally individual drive for the sections (e.g. WMS 43 E) with own frequency converter

- Central drive via ribbed V-belts and double timing belts

- Defined particle size distribution for espresso as well as for filter coffee and instant coffee grinding

- Depending on the model, mixer with compactor to improve the chaff pattern

- Increase of the bulk density

- Continuous adjustment of the compactor

- Automatic disengagement of the roll in case of foreign object passage

- Dust-proof design and sound insulation of the complete grinder

Options

- Motors with highest efficiency for optimum energy efficiency

- Roller tempering

Laboratory Grinder LWM 100

LWM 100

The LWM 100 is particularly suitable for use in laboratories, for quality control or for small-scale production. With its highly flexible control system, it is the ideal device for your product optimisation. With the LWM 100 you can define all operational data for the desired reproducible grinding result.

The LWM 100 is the ideal machine in the field of low-dust crushing with a narrow particle size distribution. The new stainless steel design allows for quick and easy cleaning. The rolls consist of the proven, specially surface-treated chilled cast iron or optionally of stainless steel. The drive system and the control elements are housed together in a stainless steel case to save space.

Technical Features

- For capacities of a few kg up to 0.5 t/h

- Reproducible grinding results

- Crushing with a defined particle size distribution

- Highly flexible application

- Grinding without temperature increase

- Quick and easy replacement of the rolls

- Grinding gap measurement by sensor, displayed in the visualisation application

- Individual drives with separate, continuously adjustable speed control

- Control via touch screen

- Automatic disengagement of the roll in case of foreign object passage

Options

- Second grinding passage

- Control via PC and monitor

- Air-flushed rotary shaft seals

Neogrind

Most modern grinder for medium capacities and specialities

The newly designed coffee grinder Neogrind has been developed specifically for the requirements for filter coffee, pad/pod production and fine grinding. Technically, this three-passage grinder offers wider rolls and higher flexibility through individual drive. The closed housing is characterized by low noise, but also a fully accessible grinding chamber.

Other features are the IE3 motors of the same size for maximum energy efficiency and a lightweight, completely bolted, corrosion resistant frame. The grinding gap is adjusted via servomotors and is provided with an automatic zero adjustment.

Technical Features

- Individual drives for all three sections, optional with own frequency converter

- Highly flexible grinder

- Dust-tight design of the complete grinder in stainless steel

- New technology of the deflector plates

- No losable parts in the grinding chamber

- No compressed air necessary, grinding gap adjustment via servomotor and automatic zero adjustment

- Fast roll change < 2 hours

- Defined particle size distribution for filter, espresso and fine grinding

- Continuous adjustment of the compactor

- Automatic disengagement of the roll in case of foreign object passage

- Dust-proof design and sound insulation of the complete grinder

- Emission values of 78 dB are complied with

- Temperature monitor

Options

- Roller tempering

- Vibration monitor