Response Benchtop Filler

Reduces Waste, Increases Profitability

Quick-Strip Design Minimises Downtime

Delivery Within Days

Product Specification:

- Fast filling, up to 40 containers per minute.

- Fills bottles, jars, tubes, vials, syringes, tubs, pots and more.

- Exceptional accuracy of up to ±0.25% reduces waste.

- 316L stainless steel / PTFE pharma and food quality compliant contact parts.

- Fill volumes from 3ml to 1L.

- Fully strip for cleaning in as little as 3 minutes.

- Choose from one or two filling heads.

- Versatile; interchangeable nozzles available for different products, including liquids, oils, gels, creams, pastes and thick products with particulates.

ATEX Response Benchtop Filler

Reduces Waste, Increases Profitability

Quick-Strip Design Minimises Downtime

Delivery Within Days

Product Specification:

- CAT II B G c T 4 (135 Degrees Celsius) filling machine.

- Suitable for use in Zone 1 & Zone 2 applications.

- Made with ATEX certified pneumatic components.

- Well-engineered solutions to avoid static build up.

- Good earthing is ensured via an Earth Point at the rear.

- The hopper comes with a lid to reduce fume release.

- Various seal and O-ring options, which we will assess to ensure compatibility with your product.

- Fast filling, up to 40 containers per minute.

- Exceptional accuracy of up to ±0.25% reduces waste.

- Fill volumes from 3ml to 1L.

- Fully strip for cleaning in as little as 3 minutes.

- Versatile; interchangeable nozzles available for different products, including liquids, oils, gels, creams, pastes and thick products with particulates.

- Compliance peace of mind: we have lodged a technical file (09XT005) with an approved body.

XYZ Distributor

Reduces Waste, Increases Profitability

Make the Most of Your Space

Delivery Within Days

Product Specification:

- Combines with our Accuramatic Peristaltic Dispensing Unit (available to purchase separately).

- Fills bottles, vials and nested syringes.

- Quick and efficient filling, up to 36ml per second.

- Exceptional filling accuracy of up to +/-0.5% reduces costly product waste.

- Compact space-efficient footprint.

- Infallible hygiene levels; the liquid only comes into contact with a length of silicone tubing, which will withstand repeated sterilisation. This produces a completely closed system, to eliminate the risk of cross contamination.

Please Note: Maximum container height 200mm. Minimum neck diameter 6-8mm.

Accuramatic Peristaltic Dispensing Unit

Reduces Waste, Increases Profitability

Make the Most of Your Space

Delivery Within Days

Product Specification:

- Fill volumes 1 - 1,000ml.

- Quick and efficient filling, up to 36ml per second.

- Exceptional filling accuracy of up to +/-0.5% reduces costly product waste.

- Combines with the XYZ Distributor to fill bottles, vials and nested syringes, or the Filling Jig for ampoules.

- Compact space-efficient footprint.

- Can be operated by hand, foot switch, or be left to cycle automatically.

- Infallible hygiene levels; the liquid only comes into contact with a length of silicone tubing, which will withstand repeated sterilisation. This produces a completely closed system, to eliminate the risk of cross contamination.

- Bacteriological inline filtration can be performed at the outlet side of the pump.

Choose from 3 filling modes:

– Braked stop

– Soft stop

– Stop with suck back

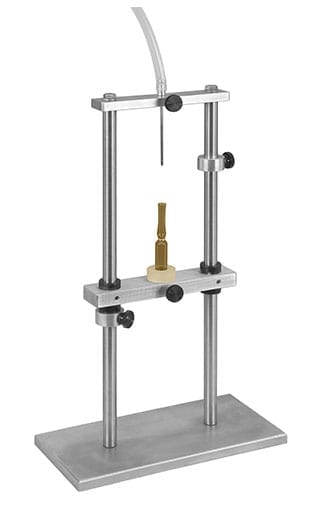

Ampoule Filling Jig

Reduces Waste, Increases Profitability

Simple & Intuitive to Use

Delivery Within Days

Product Specification:

- For use with the Accuramatic Peristaltic Dispensing Unit.

- Ensures clean filling, without wetting the ampoule wall where it is to be sealed.

- Exceptional filling accuracy of up to +/-0.5% reduces product waste.

- Hygienic, durable metal construction.

- Compact design: 210 x 105 x 345 mm.

- Operation: the ampoule is placed in a custom made holder and raised by hand to a predetermined stop, when the needle will be centred inside the container

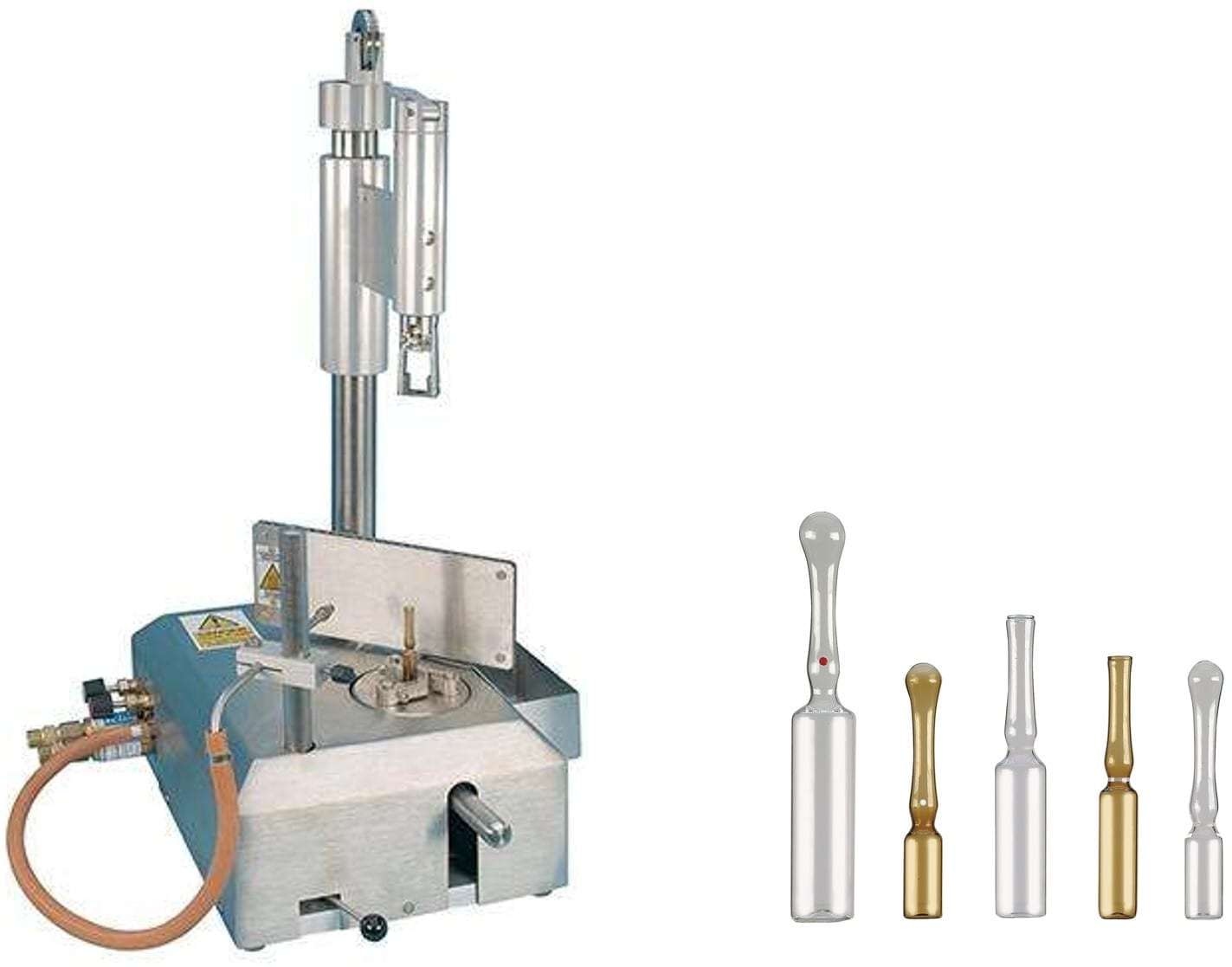

OC Ampoule Opener & Sealer

Professional Quality

Equivalent to an Automatic Machine

Up to 600 Ampoules per Hour

Product Specification:

- Quick and efficient.

- Opening and sealing of 1 - 50ml ampoules.

- Ideal for closed-type ampoules, obviating the need for washing.

- For use with natural gas or propane at 0.5 bar.

- ‘Safety First’ flash back arresters fitted to the gas inlets.

- A 110v 60Hz version can be made to order.

- Versatile; although specially designed to handle closed-type ampoules, the OC will also handle open-type ampoules after washing.

Pack size: 1 wooden case, 50x40x80cm, 40kg (approx.)

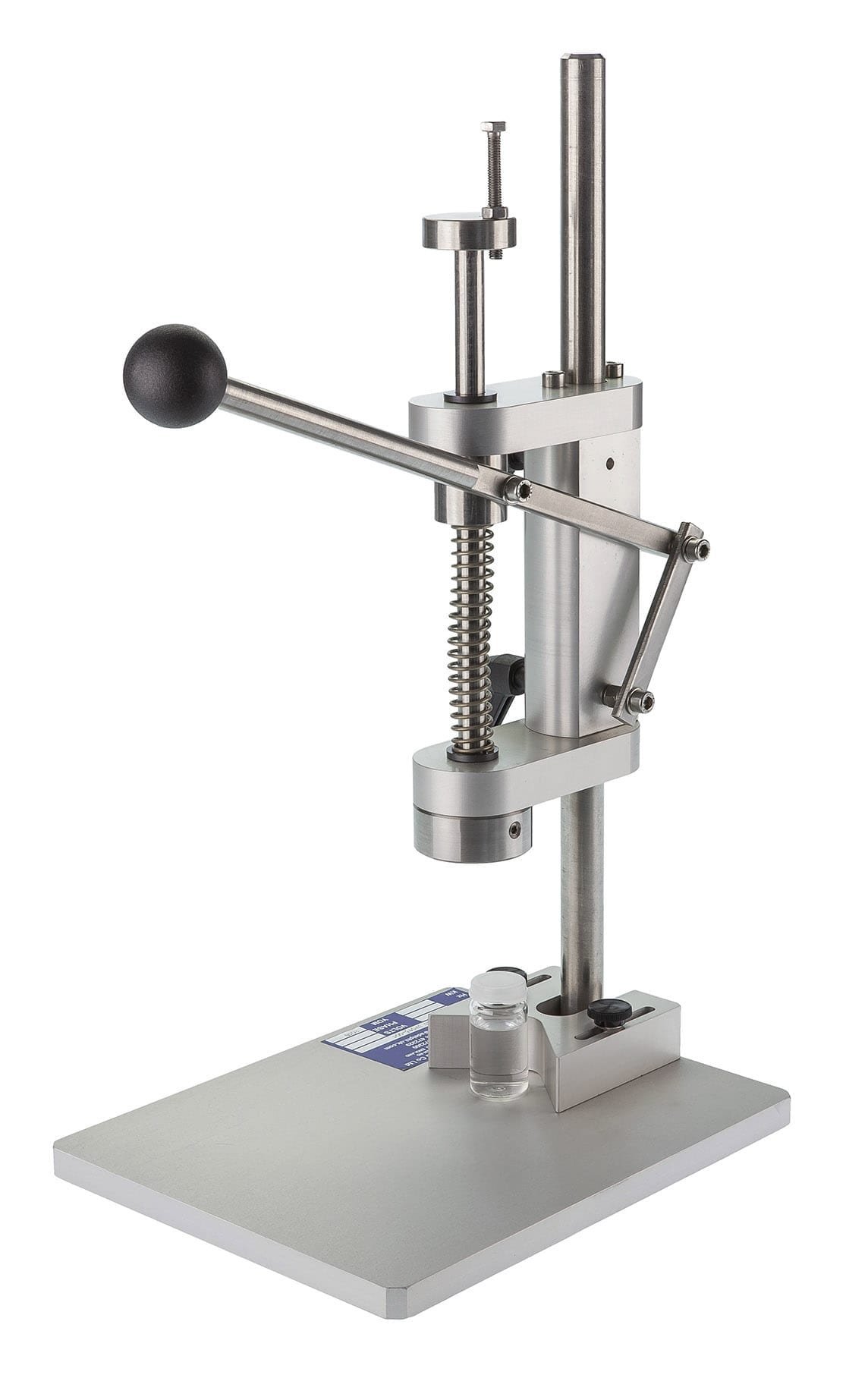

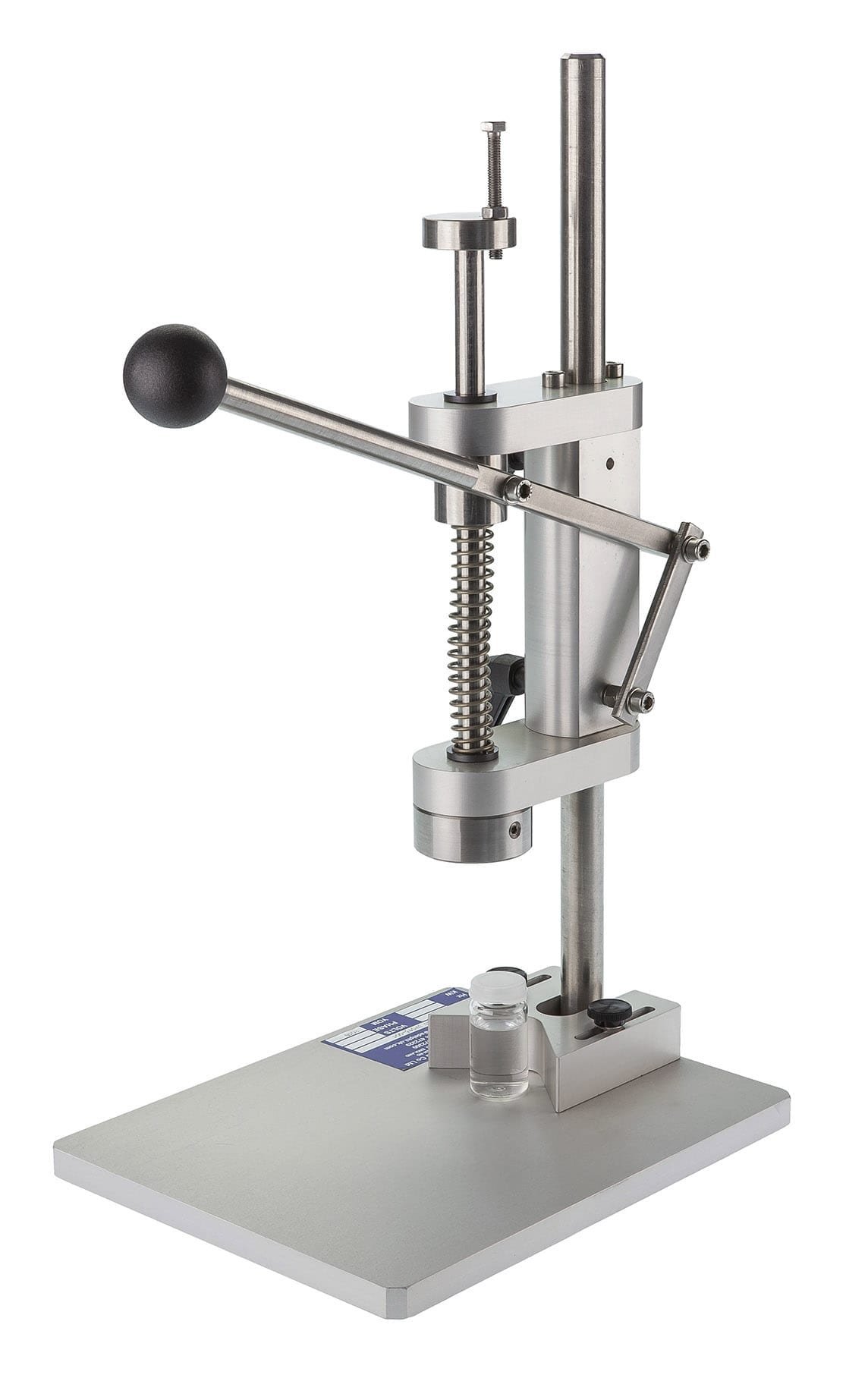

Syringe Stopper Press

Simple & Intuitive Operation

Fully Adjustable for Operator Safety

Delivery Within Days

Product Specification:

- To accommodate glass or plastic syringes of 6.35mm bore or greater.

- Easy and efficient insertion of stoppers into pre-filled syringes, ensuring that all air is expelled.

- Hygienic 316L pharmaceutical grade stainless steel contact parts, to eliminate the risk of contamination.

- Fully adjustable design for operator comfort and safety.

- The unit comprises a syringe holding jig, lever operated stopper press, and a divide for aiding the removal of air from the syringe.

Pneumatic Cap Press

Quick, Efficient & Adaptable

Simple & Intuitive to Use

Up to 600 Containers per Hour

Product Specification:

- Simple and intuitive fixing of press-on lids and caps to glass or plastic bottles.

- Approximate output of 6 – 10 containers per minute.

- Container diameters from 22 - 85mm.

- Maximum container height 240mm.

- Adjustable height and depth to accommodate a wide range of containers.

- Hygienic, durable anodised aluminium and stainless steel construction.

- Bespoke press pads to suit shaped caps can be made to suit your samples.

Manual Bottle Cap Press

Quick, Efficient & Adaptable

Simple & Intuitive to Use

Up to 1,000 Containers per Hour

Product Specification:

- A bench top, hand operated, spring loaded machine.

- Exceptional output, up to 1,000/h.

- Bottle sizes: up to 100mm diameter, up to 240mm high.

- Enable easy fixing of press-on lids and caps to glass or plastic bottles.

- Adjustable height and depth to accommodate a wide range of container heights and cap diameters.

Pneumatic Bottle Capping Machine

Quick, Efficient & Adaptable

Simple & Intuitive to Use

Up to 500 Containers per Hour

Product Specification:

- Fast capping, up to 500 containers per hour.

- Torque range 0.3NM to 4NM.

- The closure torque is manually adjustable through mechanical friction.

- Easy and efficient closing of twist-off caps.

- Robust, portable and low maintenance.

- Hygienic stainless steel and aluminium construction.

- Can be adapted to a wide range of cap sizes by changing only the cap chuck.

Bottle / Vial / Syringe / Test Tube Washer

Quick, Efficient & Thorough

Up to 900 Containers per Hour

Delivery Within Days

Product Specification:

- For container neck diameters between 9.5 mm and 100 mm.

- Thorough cleaning; jets of water clean every part of the container interior.

- Interchangeable nozzles so the unit can be used to wash bottles, vials, syringes and/or test tubes.

- Four armed container rest is easily cleaned or replaced.

- May be attached to the mains directly by plumbing, or on a stand with a pipe connected to a tap.

Please Note: Requires water at pressure not exceeding 2 bar.

Professional Quality Crimping

Simple & Intuitive to Use

Delivery Within Days

Product Specification:

- Options for ‘plain’, ‘flip top/flip off’ and ‘flip tear up’ seals.

- Crimping and de-capping of 13, 18 and 20mm seals.

- Fast and reliable, for a professional quality finish.

- Easy, intuitive operation.

- Hardened, durable steel jaws to ensure reproducibility of seal crimp quality.

- Adjustable stop, to ensure that equal pressure is applied to each crimp.

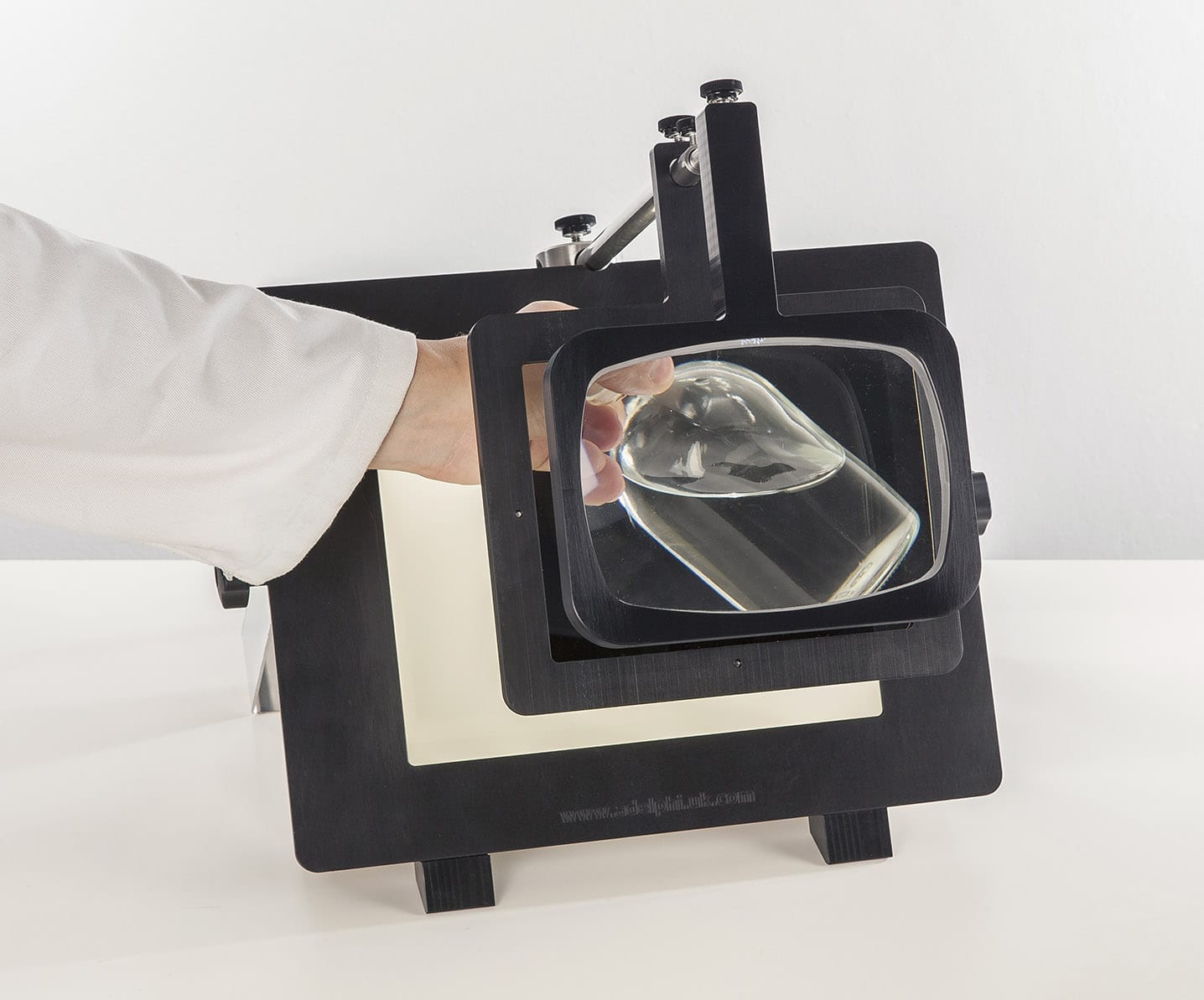

Apollo I Liquid Inspection Unit

Simple Particulate Detection

1.7x Magnification for Infallible Results

Delivery Within Days

Product Specification:

- Simple detection of unwanted particulate contamination in injections and intravenous infusions.

- Hygienic stainless steel construction.

- LED light source for durable bulb life.

- Intuitive assembly; get started straight away.

- Adjustable height and angle reduce operator fatigue.

- Optional IQ/OQ documentation.

- User manual available in English (additional languages upon request).

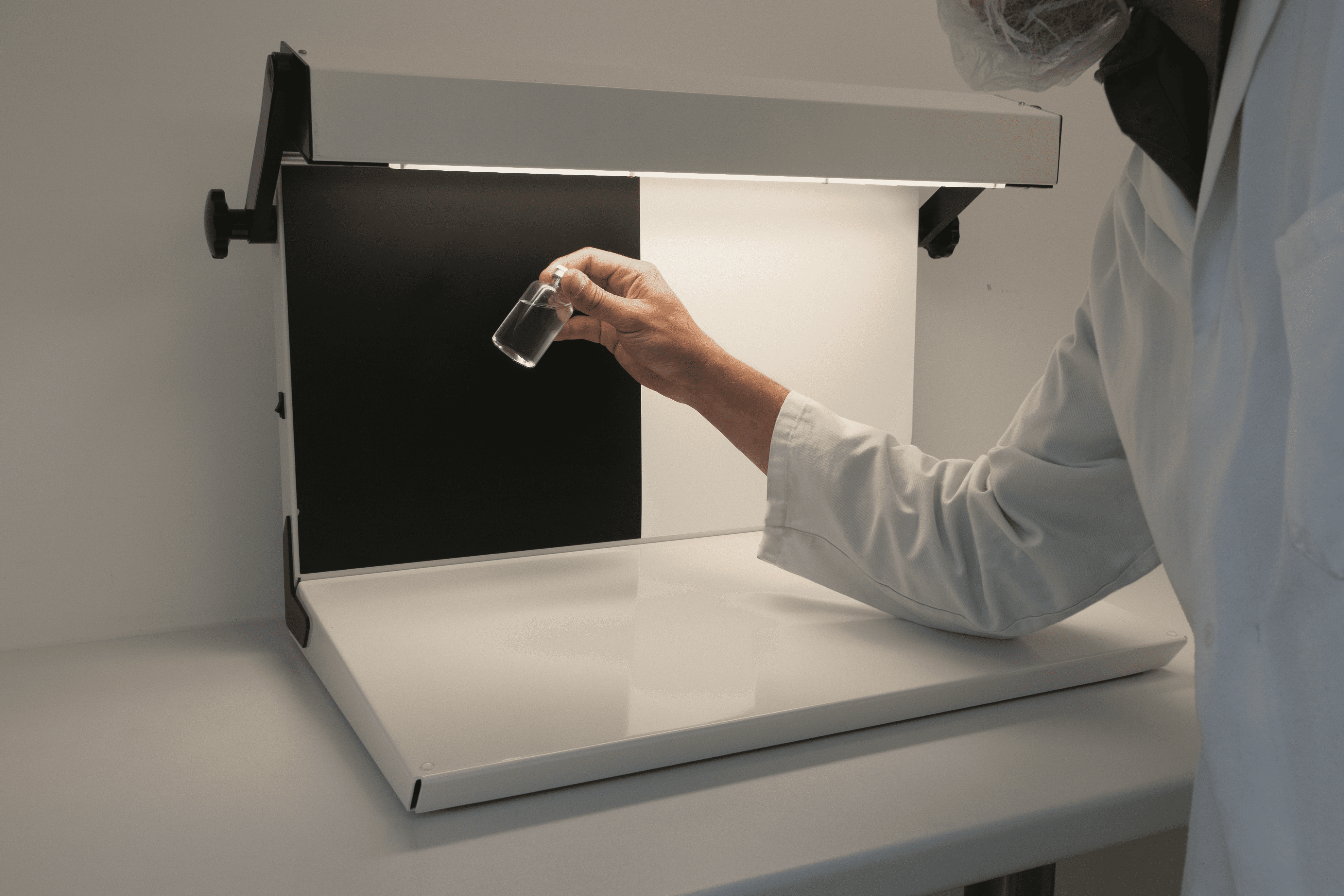

Apollo II Liquid Inspection Unit

Simple Particulate Detection

EU & US Pharmacopoeia Compliant

Delivery Within Days

Product Specification:

- For transparent glass containers.

- In front of the black panel, light coloured particulates will be visible, and in front of the white panel, dark coloured particulates will be visible.

- Compliant with

- European Pharmacopoeia Specification 2.9.20

- US Pharmacopoeia USP chapter 41 (1790), section 6.1 - Height and angle adjustable.

- Intuitive assembly; no tools required.

- Light level between 2,000 and 3,750 Lux.

- Bulbs have a service life of 50,000 hours.

- Folds for storage, with the inspection surfaces together to prevent damage.

- Optional IQ/OQ documentation.

- User manuals are available in English, Spanish, French, German, Dutch and Czech – additional languages also available upon request.

HS code is 9031 80 80 00

Pack size: 76 x 53 x 37cm @ approx. 11kg (gross weight, net weight approx. 8kg)

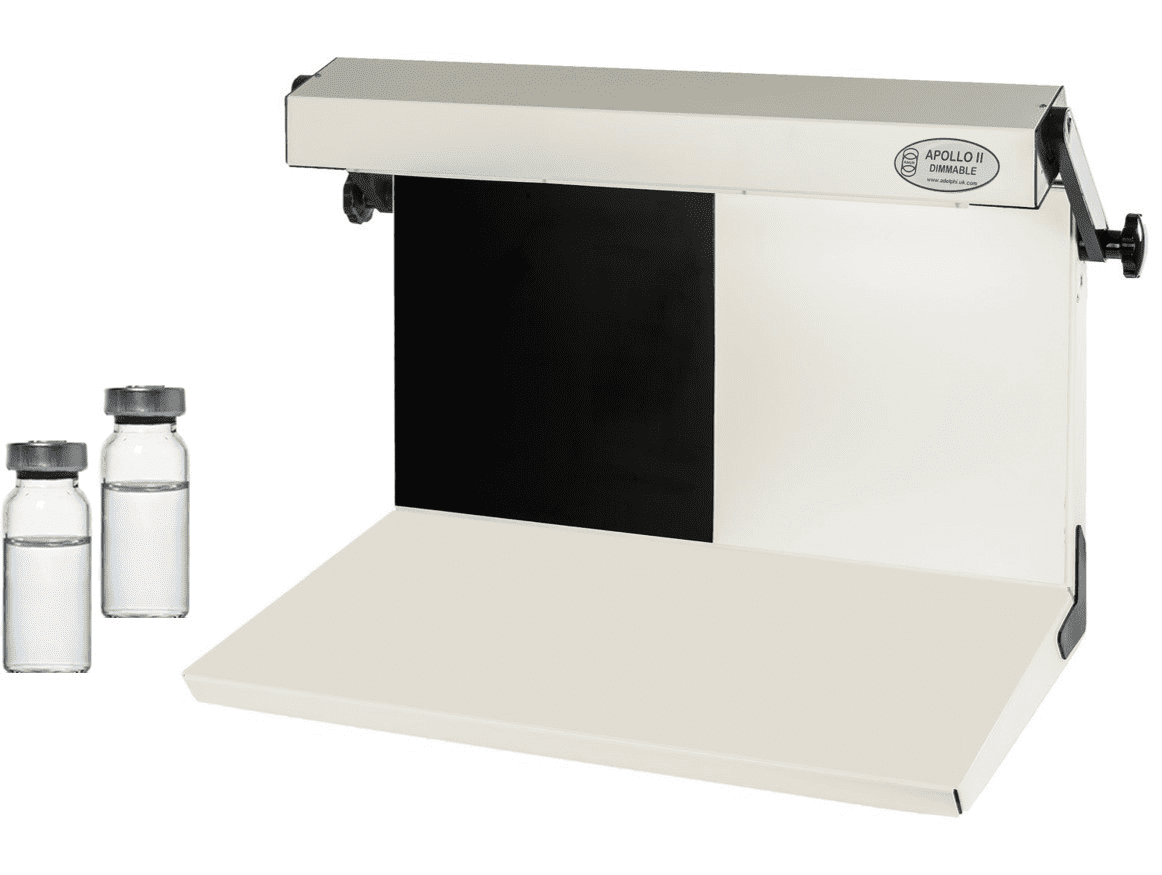

Apollo II Dimmable Liquid Viewer

Simple Particulate Detection

Adjustable Light Level Control

Delivery Within Days

Product Specification:

- In front of the black panel, light coloured particulates will be visible, and in front of the white panel, dark coloured particulates will be visible.

- Height and angle adjustable.

- Intuitive assembly; no tools required.

- Light level between 1,200 and 3,500 Lux: adjustable by dimmer control, depending on the light in the room.

- Bulbs have a service life of 50,000 hours.

- Folds for storage, with the inspection surfaces together to prevent damage.

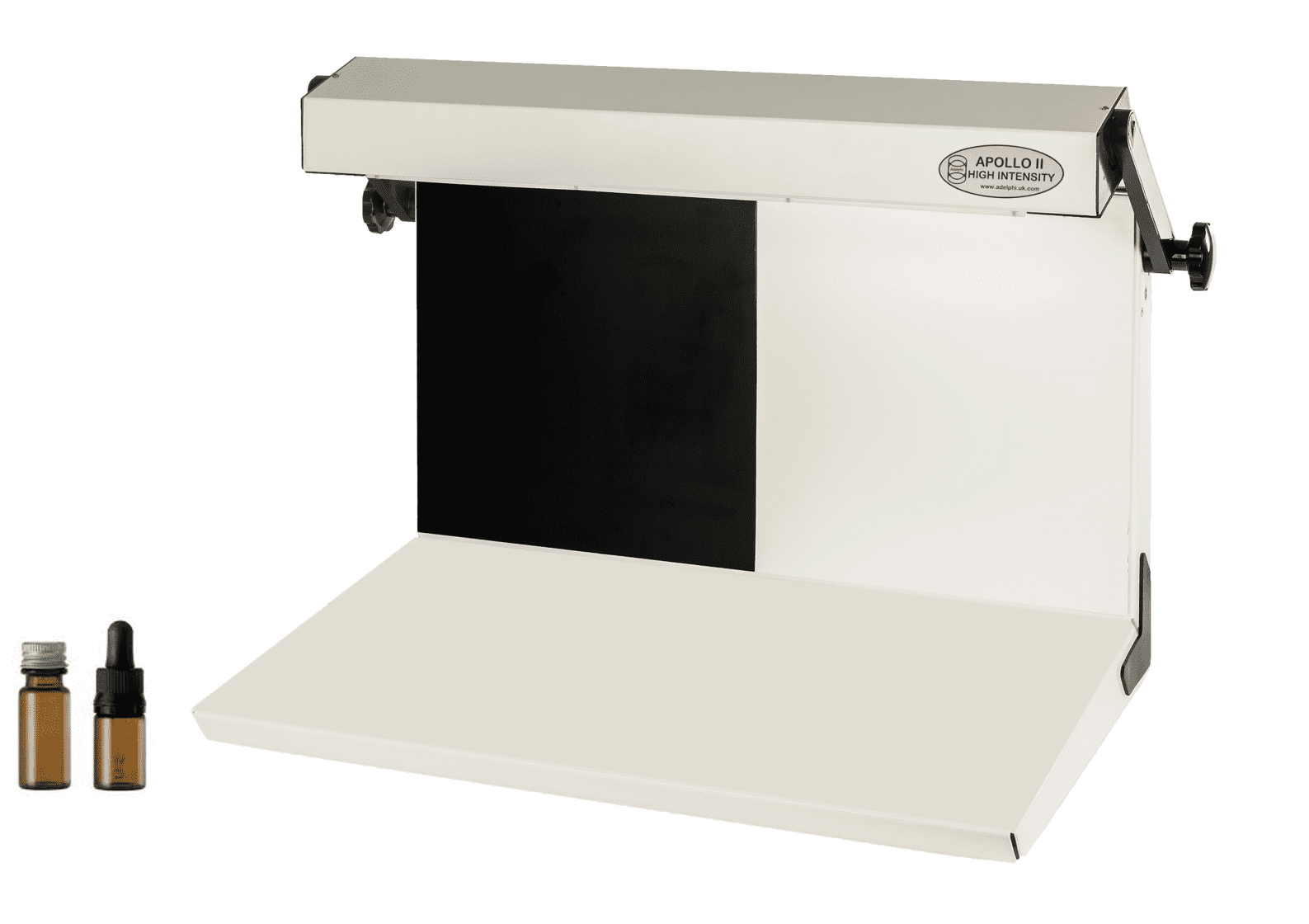

Apollo II High Intensity Liquid Inspection Unit

Simple Particulate Detection

EU & US Pharmacopoeia Compliant

Delivery Within Days

Product Specification:

- For coloured glass containers.

- In front of the black panel, light coloured particulates will be visible, and in front of the white panel, dark coloured particulates will be visible.

- Compliant with

- European Pharmacopoeia Specification 2.9.20

- US Pharmacopoeia USP chapter 41 (1790), section 6.1 - Height and angle adjustable.

- Intuitive assembly; no tools required.

- Light level between 8,000 and 10,000 Lux.

- Bulbs have a service life of 50,000 hours.

- Folds for storage, with the inspection surfaces together to prevent damage.

- Optional IQ/OQ documentation.

ProFiller 1100 Capsule Filler

Fast & Accurate

Pharmacopoeia Quality Compliant

Up to 3,400 Capsules per Hour

Product Specification:

- Efficiently orients, separates, fills and fully locks 100 capsules at a time.

- Patented design, up to 35% faster than similar capsule fillers.

- Highly accurate filling to within ± 1-2% of the average weight using the USP/EP method, reduces waste.

- Change parts in sizes 000-5 and all el sizes.

- ProFill 100 OE available for sizes AAA-D.

- Hygienic, durable 316L pharmaceutical grade stainless steel construction.

- Fully dishwasher safe.

- Quick and easy to disassemble without any tools.

- Change parts and a full range of accessories, such as powder vibrators, are available upon request.

For customers with higher output requirements, we also offer:

- Profiller 1120 - up to 3,600 per hour

- Profiller 3600 - up to 6,900 per hour

- Profiller 3700 - up to 9,000 per hour

- Profiller 3800 - up to 9,000 per hour

For smaller batch capsule counting:

- Rectangular Capsule Counting Tray

- Tumatic Capsule & Tablet Counter

- Lifting Leaf Capsule & Tablet Counter

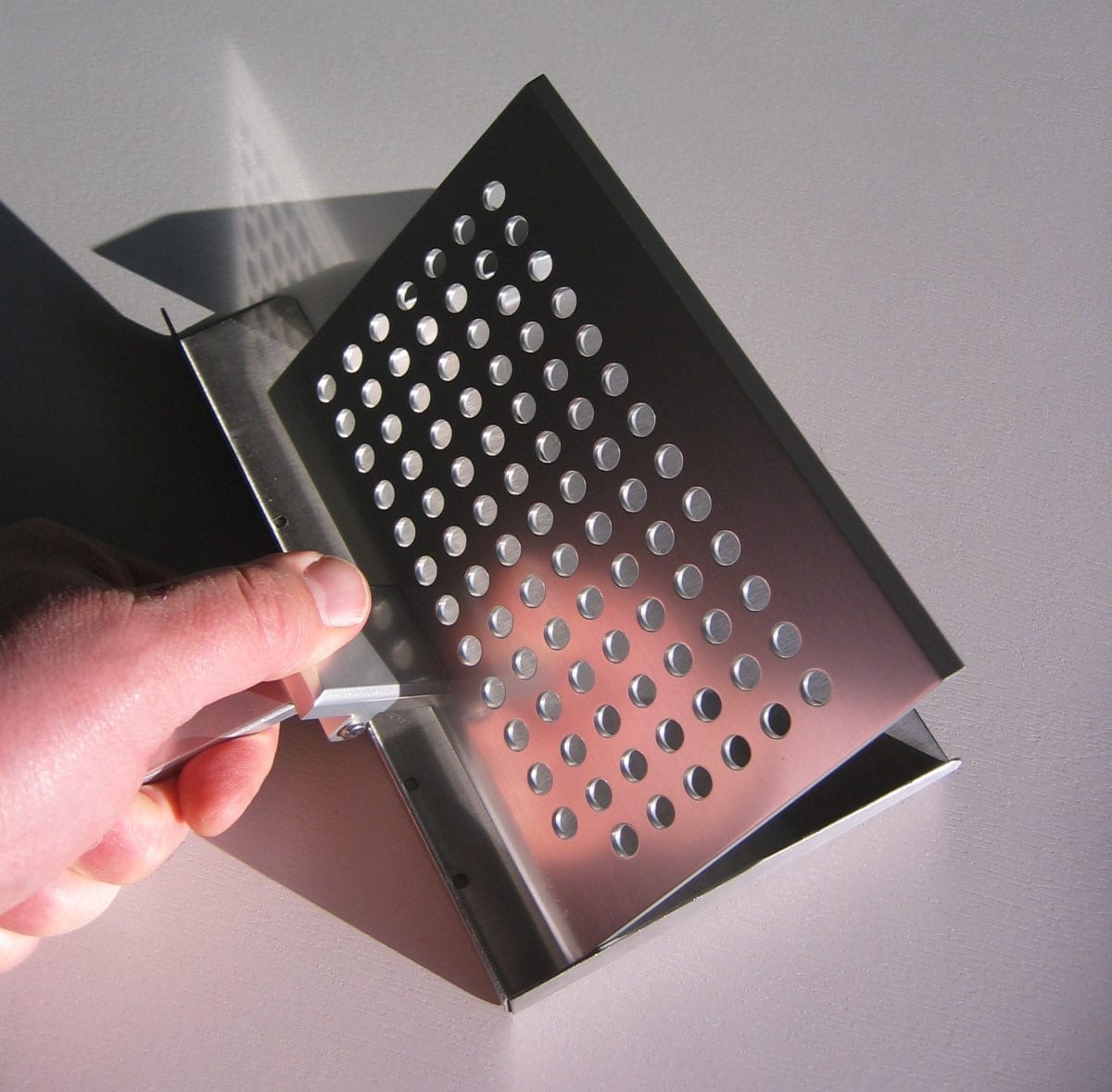

Lifting Leaf Tablet & Capsule Counter

Durable & Re-Useable

Fast & Accurate

Made to Meet Your Specification

Product Specification:

- Quick and accurate counting of both coated and uncoated tablets and capsules.

- Hygienic, durable stainless steel, anodised aluminium and polycarbonate construction.

- Dispenses up to 100 tablets or capsules at a time, dependent on size.

- Made to order, to precisely match your samples.

Operation: The counter is used like a scoop and pushed into a pile of tablets. The requisite number of tablets or capsules fall into the holes and the excess shaken off. The counter is then tilted back and used as a chute for filling bottles.

For customers with higher output requirements, we also offer:

- Profiller 1100 - up to 3,400 per hour

- Profiller 1120 - up to 3,600 per hour

- Profiller 3600 - up to 6,900 per hour

- Profiller 3700 - up to 9,000 per hour

- Profiller 3800 - up to 9,000 per hour

Other smaller batch capsule counting options:

- Rectangular Capsule Counting Tray

- Tumatic Capsule & Tablet Counter

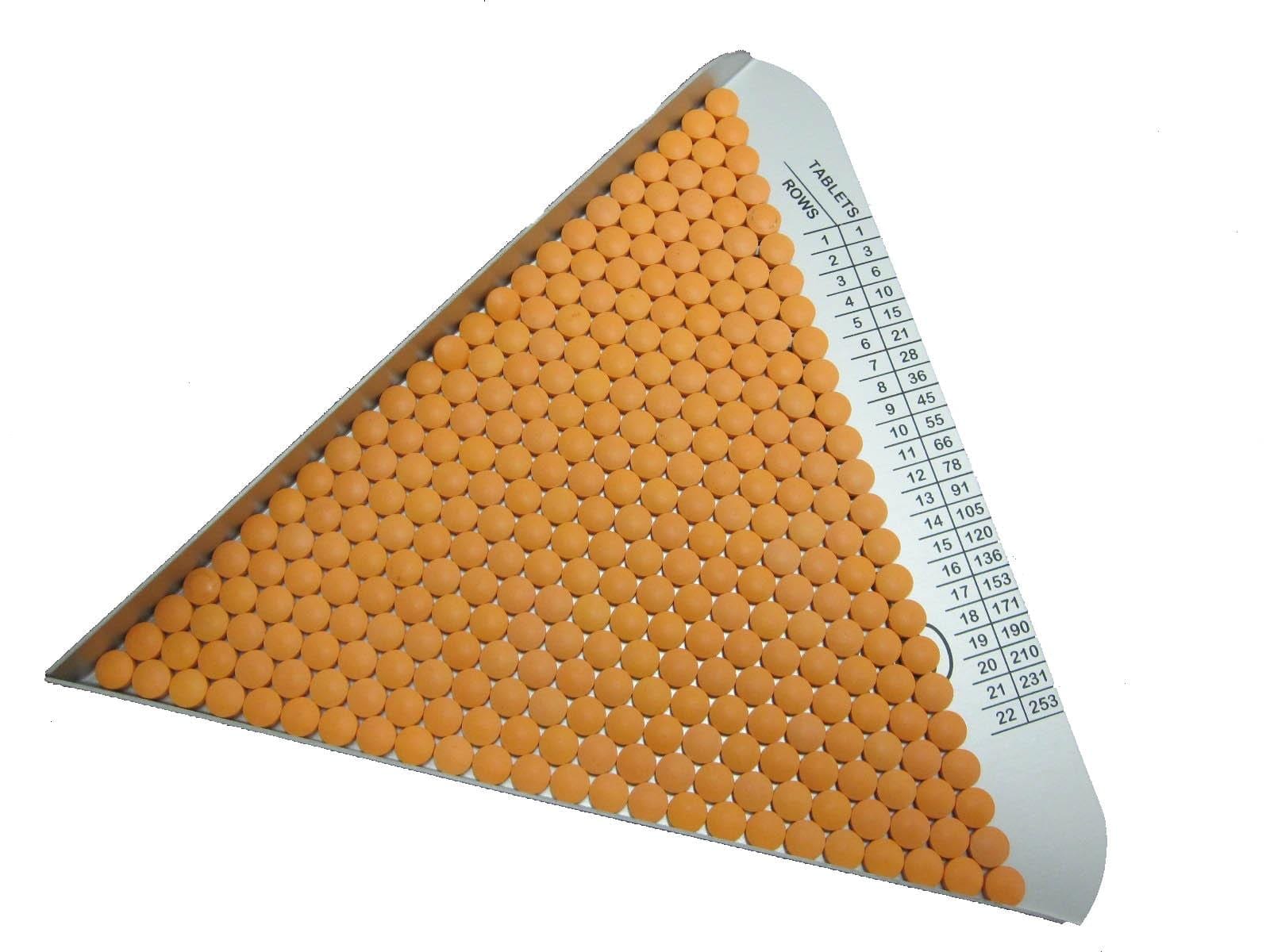

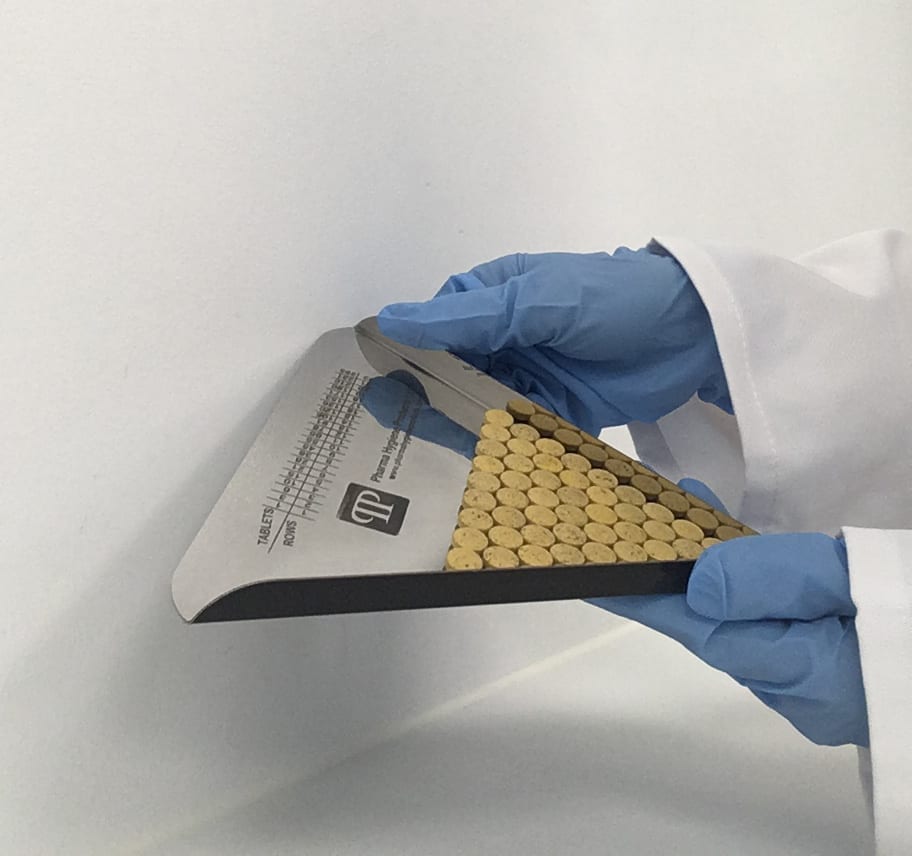

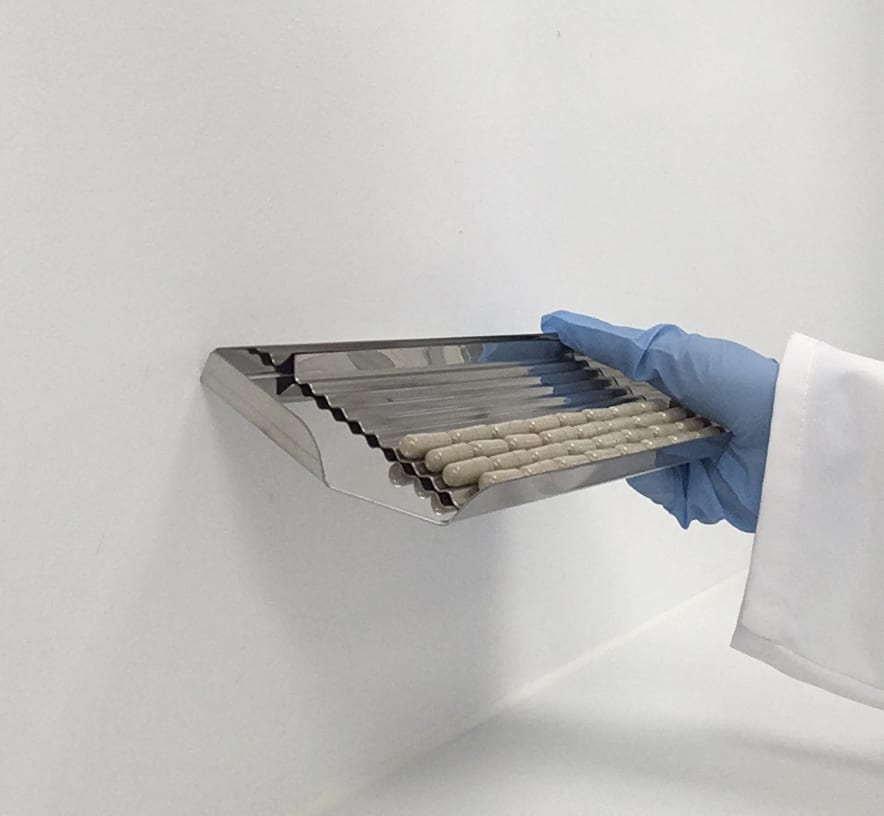

Triangular Tablet Counting Tray

Durable, Easy to Sterilise, Re-Useable

Delivery within Days

Full Material Traceability

to meet international pharma and food quality compliance regulations.

Product Specification:

- Quick and accurate counting of round tablets.

- Available in 7" and 10" sizes.

- 304 or 316L grade stainless steel.

- 316L version is electropolished to meet TSE requirements, guaranteeing that no animal fats have been used in the polishing process. This is vital to guarantee that no cross-contamination from BSE or CJD diseases occurs. Optional TSE certification is available.

- A more cost-effective and eco-conscious alternative to plastic disposable trays.

- Manual operation, which allows the user to easily see the number of round tablets in each batch, and to quickly pour them into a container.

Other small batch tablet counting options:

- Lifting Leaf Tablet & Capsule Counter

- Tumatic Tablet & Capsule Counter

For customers processing capsules, we also offer:

- Profiller 1100 - up to 3,400 per hour

- Profiller 1120 - up to 3,600 per hour

- Profiller 3600 - up to 6,900 per hour

- Profiller 3700 - up to 9,000 per hour

- Profiller 3800 - up to 9,000 per hour

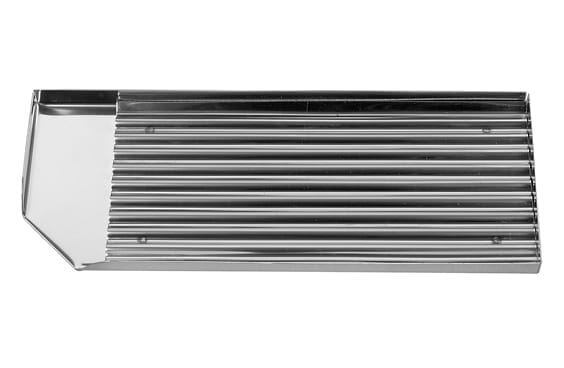

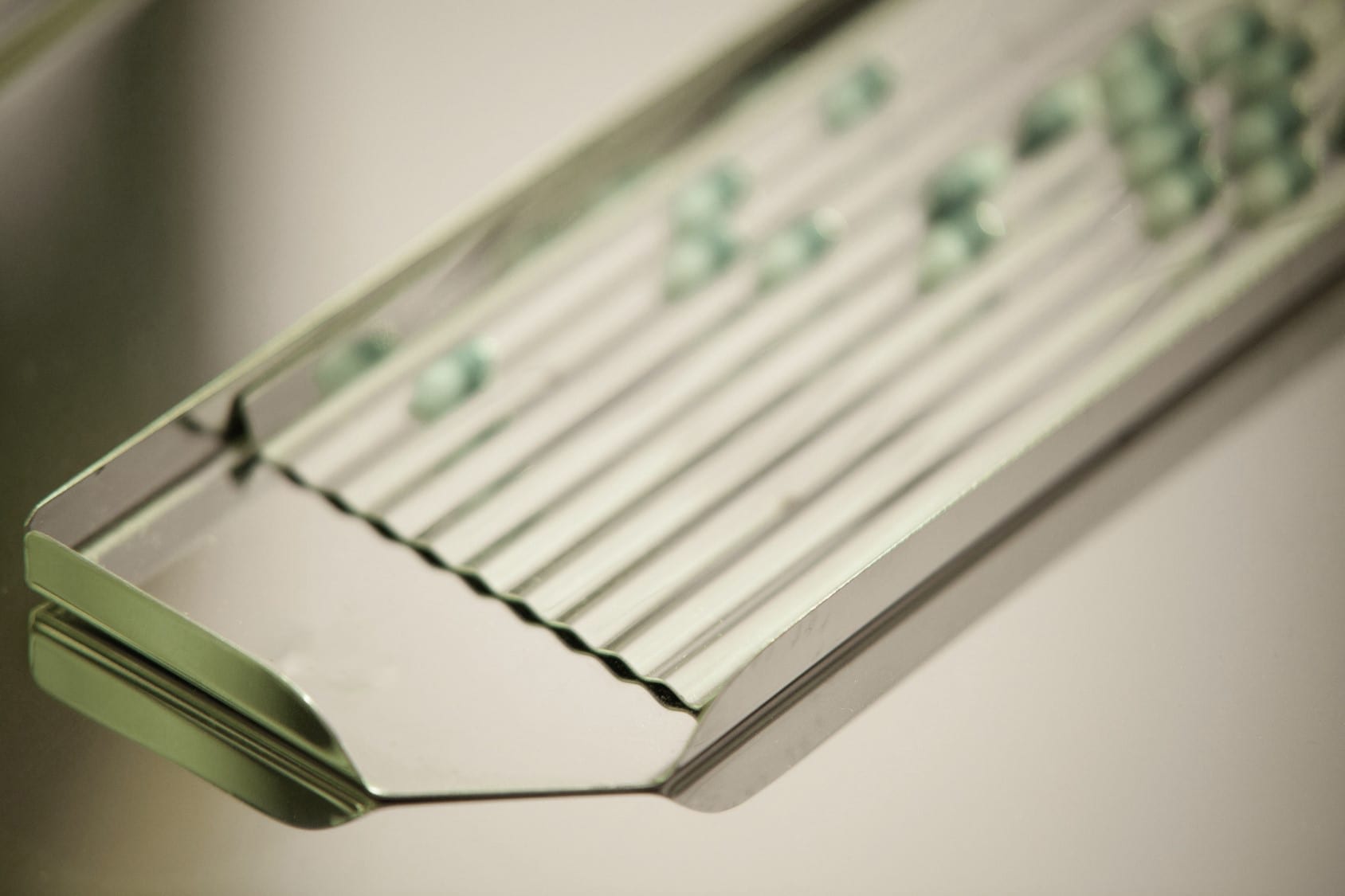

Capsule Counting Tray

Durable, Easy to Sterilise, Re-Useable

Delivery within Days

Full Material Traceability

to meet international pharma and food quality compliance regulations.

Product Specification:

- Hygienic 304 grade stainless steel.

- Quick and accurate counting of capsules, sizes 0 to 5 (up to 8 mm diameter).

- Available individually or in packs of 5.

- Size 175 x 88 mm.

- Can be cleaned with alcohol-based disinfectants, and in industrial dishwashers/autoclaves.

- Optional Material Grade and Surface Finish certification available upon request.

- Manual operation, which allows the user to easily see the number of capsules in each batch, and to quickly pour them into a container.

For customers with higher output requirements, we also offer:

- Profiller 1100 - up to 3,400 per hour

- Profiller 1120 - up to 3,600 per hour

- Profiller 3600 - up to 6,900 per hour

- Profiller 3700 - up to 9,000 per hour

- Profiller 3800 - up to 9,000 per hour

Other smaller batch capsule counting options:

- Tumatic Capsule & Tablet Counter

- Lifting Leaf Capsule & Tablet Counter

Response Benchtop Tube Filler

Reduces Waste, Increases Profitability

Quick-Strip Design Minimises Downtime

Delivery Within Days

Product Specification:

- Fast filling, up to 30 tubes per minute.

- Exceptional accuracy of up to ±0.25% reduces waste.

- 316L stainless steel / PTFE pharma and food quality compliant contact parts.

- Fill volumes from 3ml to 400ml.

- Fully strip for cleaning in as little as 3 minutes.

- Choose from one or two filling heads.

- Versatile; interchangeable nozzles available for different product viscosities, including gels, creams, and thick pastes.

Can be configured for use in

ATEX Zone 1 Category IIB 2G c T4 (135C).

Adelphi Manufacturing also offer:

Centrac® FCC, for closing metal tubes.

Vesta 1C for sealing plastic/laminate tubes.