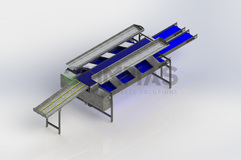

Fruit Tray (DPT_4800)

The double rotational packaging belt machine is designed to work in conjunction with sorting machines and is ideal for being a part of the final packaging segment of the processing line. The purpose of the belt machine is to hold the incoming fruits (up to 2 sizes) from the sorting machine until they are removed and packed in boxes. This is achieved by creating two belt loops, which with their constant movement gather the fruit around and in front of the packing benches.

The machine consists of:

- Two packing belts that have opposite directions of movement, split in half and joined at their ends, creating a permanent loop.

- A filled boxes conveyor belt at the center of the machine, above the packing belts.

- Workbenches with slanted packing decks, placed on both sides of the machine, where the operator places the box to be filled.

- Empty box benches, where the empty boxes are placed for easy access by the operator.

- A free roller system at the end of the filled box conveyor belt, where the filled boxes end up and are received for final packaging/palletization.

The working cycle of the machine is as follows:

- Two sizes of products from the sorter pass on to the beginning of the packing belts. Due to the movement of the belts, these products are collected in front of the benches and remain in the formed loop.

- The operator picks up an empty box from the empty box bench and places it on the slanted deck in front of him.

- The operator then fills the box with the sorted fruit and when ready, pushes it into the filled boxes belt, which carries it to the end of the machine where it is received for final packaging/palletization.

Technical Specifications:

- The frame of the machine is made of metal sheets and beams, with a double coating of anti-corrosion paint.

- The sides of the belts are lined with a special soft material to avoid damage to the fruit.

- The movement of each loop of the packing belts is done with 2 motors of 0.5 HP.

Automatic Horizontal Strapping machine

The automatic horizontal strapping machine model 06 RP, automatically pack products with one or more thermowelding polyester or polypropylene straps.

The machine consists of a sturdy structure made of arc welded steel profiles which supports all the strapping machine’s components:

- TR Head (our own international patent) located to the side of the product’s direction of travel which automatically carries out all strap feeding, recovery, tensing, welding and cutting operations.

- Track for the strap to run around the pack made of a special material featuring a special releasing device with multiple independent segments to ensure perfect strap centering around the pack.

- Strap compensation and pulling device. This occurs through the transversal compensating motion of the entire welding head during the tensioning phase. This ensures an homogenous pull on all the sides of the pack. The head’s motion is given by sleeves which slide on treated guides.

- Strap feeding group with coil holders which collects the strap through an anti-tear system and electromagnetic brake.

- Electric panel to make the machine work completely automatically and manually.

The machine comes complete with all the drive systems (electric and pneumatic) and is painted in its every part.

Standard Machine Characteristics

Strap Type: polypropylene (PP), polyester (PET) Strap Union: thermoelectric welding Applicable Strapping Heads: model TR14/TR14HD/TR18/TR19 HT Electrical Supply 400/415 V three phase 50 Hz Air pressure: min 3 bar Standard Arch dimensions 800 x 1000 mm; 800 x 1200 mm Coil holder diameter inside 390 ÷ 405 mm width 150 ÷ 160 mm.