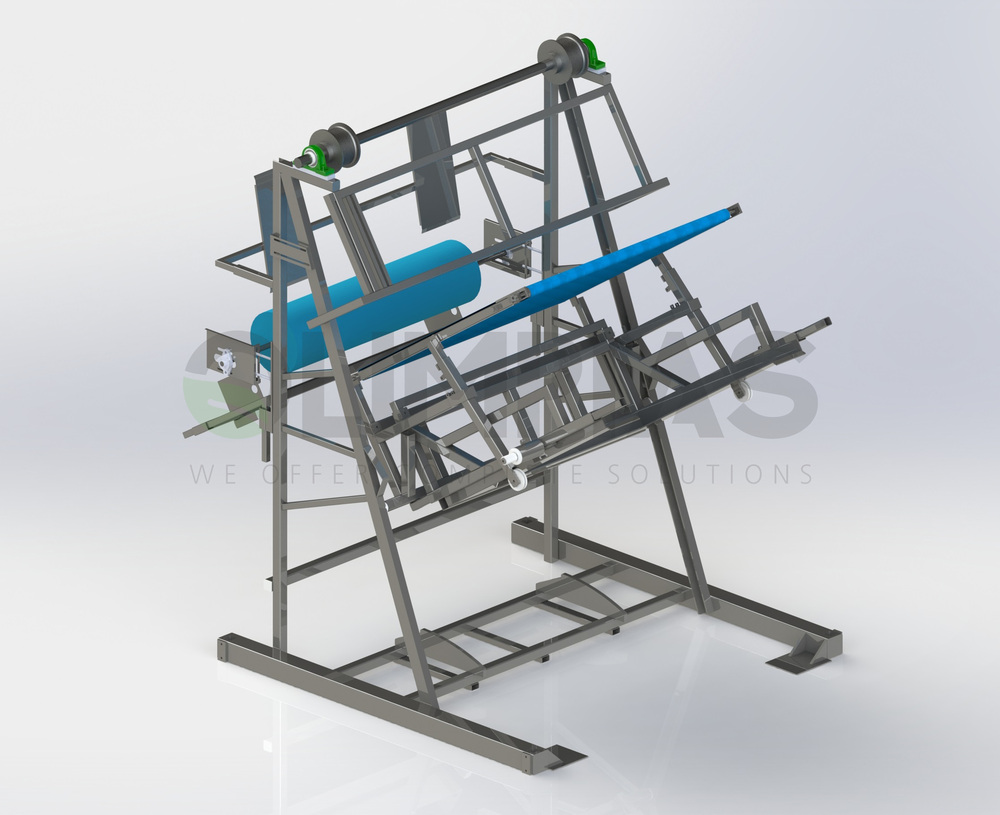

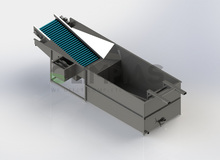

Automatic Crate/Box Tilting Unit

The Automatic Crate/Box Tilting Unit is a continuous flow machine, suitable for supplying the production line with products such as kiwis, peaches, citrus fruits, etc. The capacity varies depending on the requirements of each production line.

Through its variable speed, it enables the smooth and continuous supply of the line with products. In addition, it has two special chains that are used for the smooth transition of the boxes from the elevator to the tilting unit as well as for the correct box placement needed to achieve emptying in a smooth way.

The elevator unit has a PVC conveyor belt with large embossed teeth. In addition, there are adjustable guides on the right and left of the elevator so that it can accept various types of boxes and transport them smoothly to the tilting unit.

The machine consists of:

- the elevator – conveyor belt.

- the tilting unit.

The unit’s work cycle runs as follows:

- The boxes are transferred one after another, onto the tilting machine through the elevator conveyor belt.

- Once the boxes are at the top of the conveyor belt, they latch onto the gear which, through the necessary rotation, places them in a position to be able to be transported and tilted.

- This action is performed through the movement of chains and guide tubes.

- After the box is emptied, the chain system, with the help of the guiding tubes, transports it towards the exit for refilling/disposal.

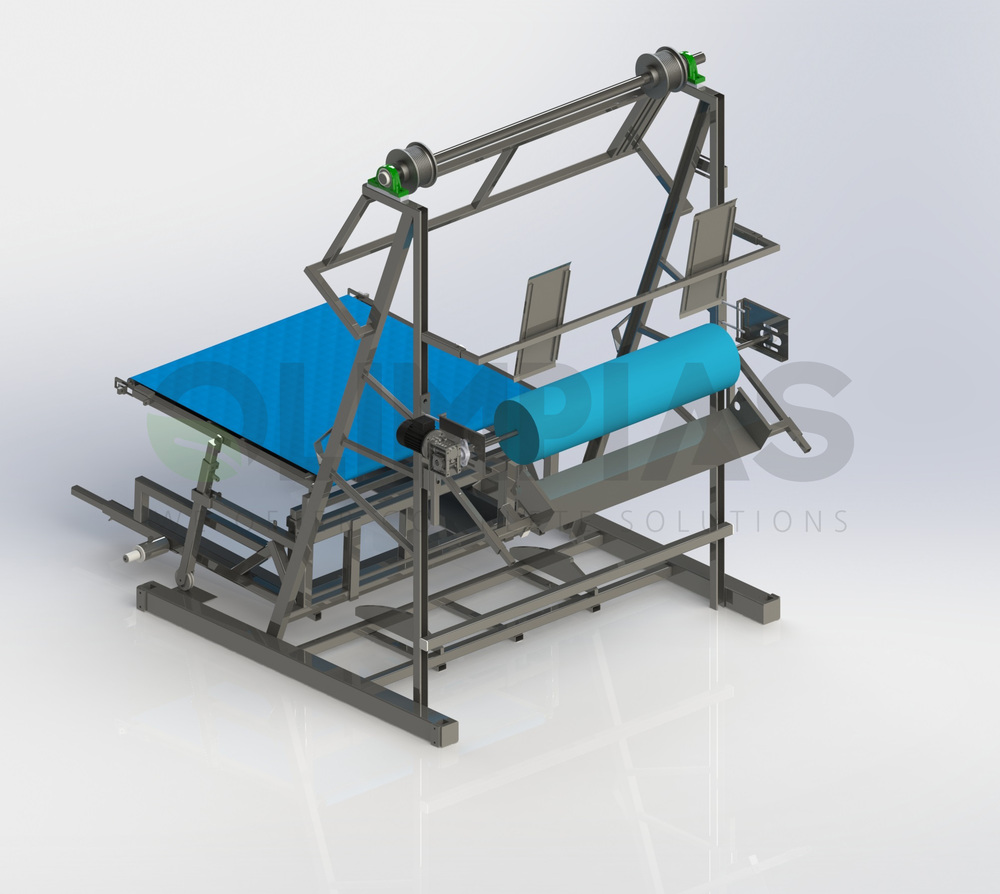

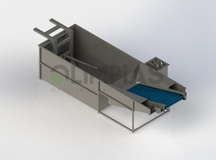

Automatic Bins Dumper

The Bins/Pallet Box dumper is ideal for continuous tipping of Bins and Pallet Boxes, with sensitive products such as apples, pears, kiwis, peaches, etc. The Bins/Pallet Box dumper ensures smooth supply with a continuous and controlled flow of the production line. An additional advantage of the machine is that it can handle all the usual box sizes.

The machine consists of two parts, (the fixed and the moving part). The moving part consists of a suitable belt on which the pallet box is placed. The belt helps the pallet box to get into the correct position on the base. For this purpose, a suitable photocell system and/ or timer have been fitted to control the smooth filling of the base with the pallet box. After the pallet has reached the proper position it starts the rollover. The entire rollover is done using a cable system. On the fixed base an additional photocell system is mounted to check if the pallet box has reached the correct rollover position to stop the movement. At that height, there is a cylindrical brush system that helps the products come out smoothly from the pallet box.

The machine includes an electrical board that contains all control and management automation. This ensures the correct and smooth operation of the process.

The capacity of the system depends on the size of the pallet box and can reach up to 30 BINS per hour.

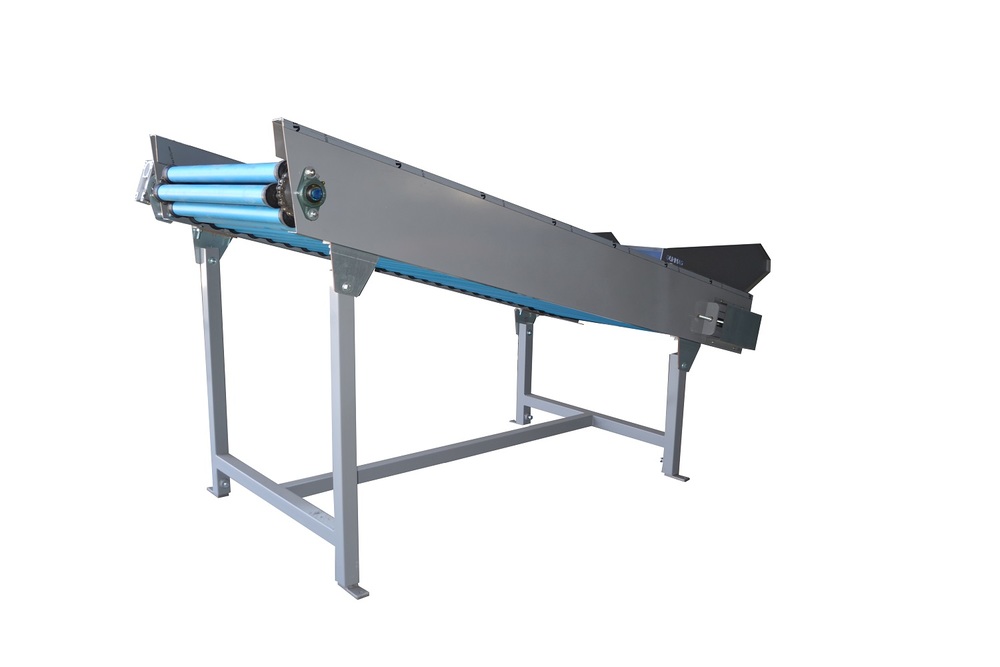

Elevator

The elevator is a specially designed machine consisting of rollers, used for fruit processing. The purpose of the elevator is to transport products from one place to another, between different heights. It is meant to be a part of a more complex processing line for packaging and/or sorting products. The machine starts running and operates through switches on the electric board. Part movements are automated.

Machine general breakdown:

- The external parts of the machine are constructed from painted structural steel framework and plates, welded and/or bolted.

- The internal parts that come in contact with the product are made of stainless steel.

- The machine’s stands are height adjustable.

- The loading hopper is lined with an elastic material in order to protect the processed products from bruising.

- The diameter of the rollers is Φ48 and the material used is subject to product requirements. Usually used materials are: PVC, Metal, Aluminium Alloy and INOX.

Product transporting speed can be adjusted mechanically or electrically through an Inverter.

The normal work cycle is as follows:

- The operator feeds the loading hopper with products.

- The products roll onto the incline roller elevator, where the moving line of rollers rotates them in such a way, giving the operator the ability to perform small-scale sorting, if desired.

The products are then transported to the end of the roller section for further processing

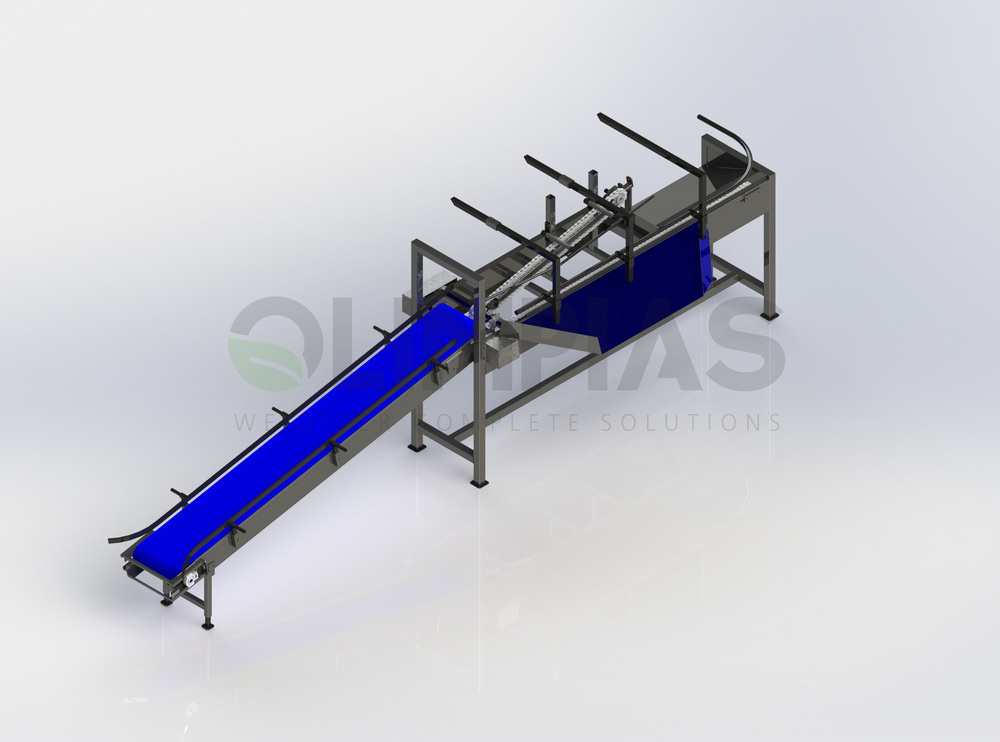

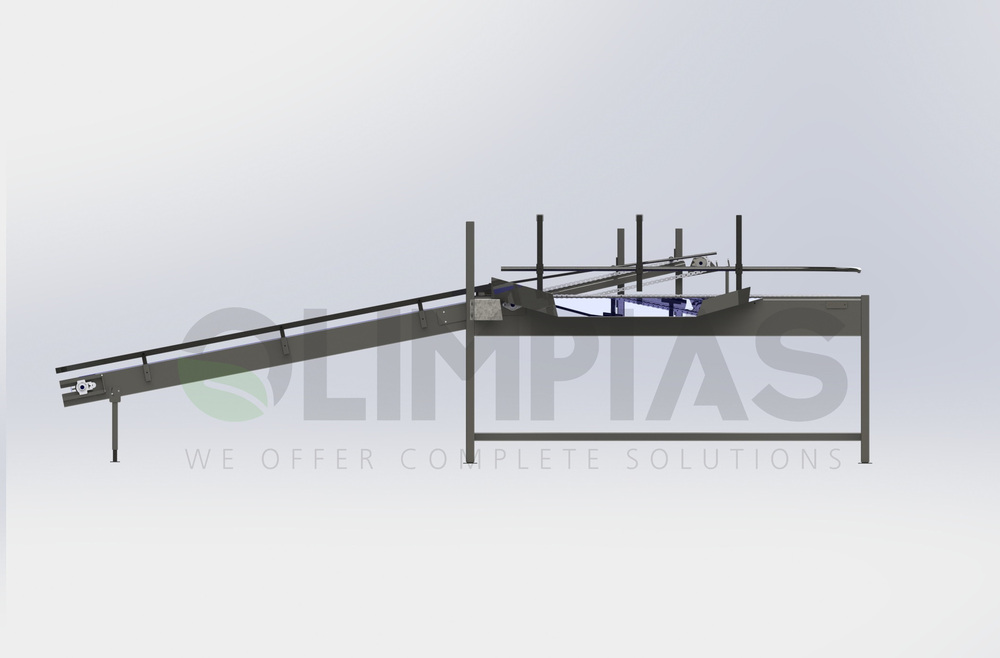

Elevator-Inspection table

The elevator – inspection table, is a specially designed machine consisting of rollers, used for fruit processing. It is meant to be a part of a more complex processing line for packaging and/or sorting products. The machine starts running and operates through switches on the electric board. Part movements are automated.

The machine consists of the following:

- Incline roller elevator.

- Inspection table.

Machine general breakdown:

- The external parts of the machine are constructed from painted structural steel framework and plates, welded and/or bolted.

- The internal parts that come in contact with the product are made of stainless steel.

- The machine’s stands are height adjustable.

- The loading hopper is lined with an elastic material to protect the processed products from bruising.

- The diameter of the rollers is Φ48 and the material used is subject to product requirements. Usually used materials are PVC, Metal, Aluminium Alloy, and INOX.

Product transporting speed can be adjusted mechanically or electrically through an Inverter.

The normal work cycle is as follows:

- The operator feeds the loading hopper with products.

- The products roll onto the incline roller elevator and inspection table, where the moving – rotating line of rollers rotates them in such a way, to facilitate the operator in the sorting process.

- Staff performs manual visual control and inspection of the products on the inspection table.

- The products are then transported to the end of the roller section for further processing.

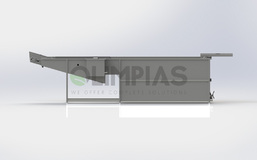

Water Tank with Elevator

The purpose of the water tank-elevator machine is to feed and transport products from their storage containers (pallet boxes) to the processing line. The machine consists of the following:

- The special forklift pickup forks, the purpose of which is to submerge the pallet box into the tank.

- The water pump, which fills the tank with water, and regulates its flow & circulation.

- The tank, the purpose of which is to store water.

- The elevator.

- The elevator motor, regulates its motion.

The purpose of the machine is fulfilled by the following procedure:

- Initially, the product pallet box is submerged in the water tank, where the products are released due to buoyancy and float on the surface of the water.

- Then the products, due to the circulation of water in the tank, are pushed towards the elevator, which is installed on the side of the tank.

- Finally, the products latch onto the rollers of the elevator which, with their rotational and translational motion, trap and transport the products from the tank to the end of the elevator, for further processing.

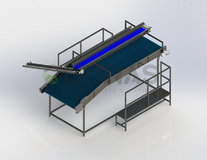

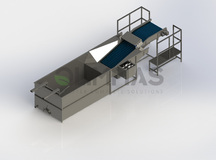

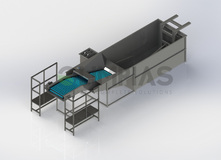

Water Tank with Sorting Table

The purpose of the water tank-elevator-sorting table machine is to feed and transport products from their storage containers (pallet boxes) to the processing line. The machine consists of the following:

- The special forklift pickup forks, the purpose of which is submerging the packaging into the tank.

- The water pump, which fills the tank with water, and regulates its flow & circulation.

- The tank, the purpose of which is to store water.

- The elevator.

- The sorting table.

- The elevator/sorting table motor, which regulates their motion.

The purpose of the machine is fulfilled by the following procedure:

- Initially, the product pallet box is submerged in the water tank, where the products are released due to buoyancy and float on the surface of the water.

- The products, due to the circulation of water in the tank, are pushed towards the elevator, which is installed on the side of the tank.

- Then, the products latch onto the rollers of the elevator which, with their rotational and translational motion, trap and transport them from the tank to the sorting table.

- Finally, at the sorting table, staff performs manual visual control, inspection, and sorting/removal of the products deemed unsuitable for further processing.

Sorting Table

The sorting-inspection table, is a specially designed machine consisting of rollers, used for fruit processing. It is meant to be a part of a more complex processing line for packaging and/or sorting products. The machine starts running and operates through switches on the electric board. Part movements are automated.

Product transporting speed can be adjusted mechanically or electrically through an Inverter.

The normal work cycle is as follows:

- The products roll onto the inspection table, where the moving – rotating line of rollers rotates them in such a way, allowing the operators to see the whole surface of the fruits.

- Staff performs manual visual control and inspection of the products.

- The products are then transported to the end of the roller section for further processing.

Machine general breakdown:

- The external parts of the machine are constructed from painted structural steel framework and plates, welded and/or bolted.

- The internal parts that come in contact with the product are made of stainless steel.

- The machine’s stands are height adjustable.

- The loading hopper is lined with an elastic material in order to protect the processed products from bruising.

- The diameter of the rollers is Φ48 and the material used is subject to product requirements. Usually used materials are: PVC, Metal, Aluminium Alloy and INOX.