Mechanical Sizers

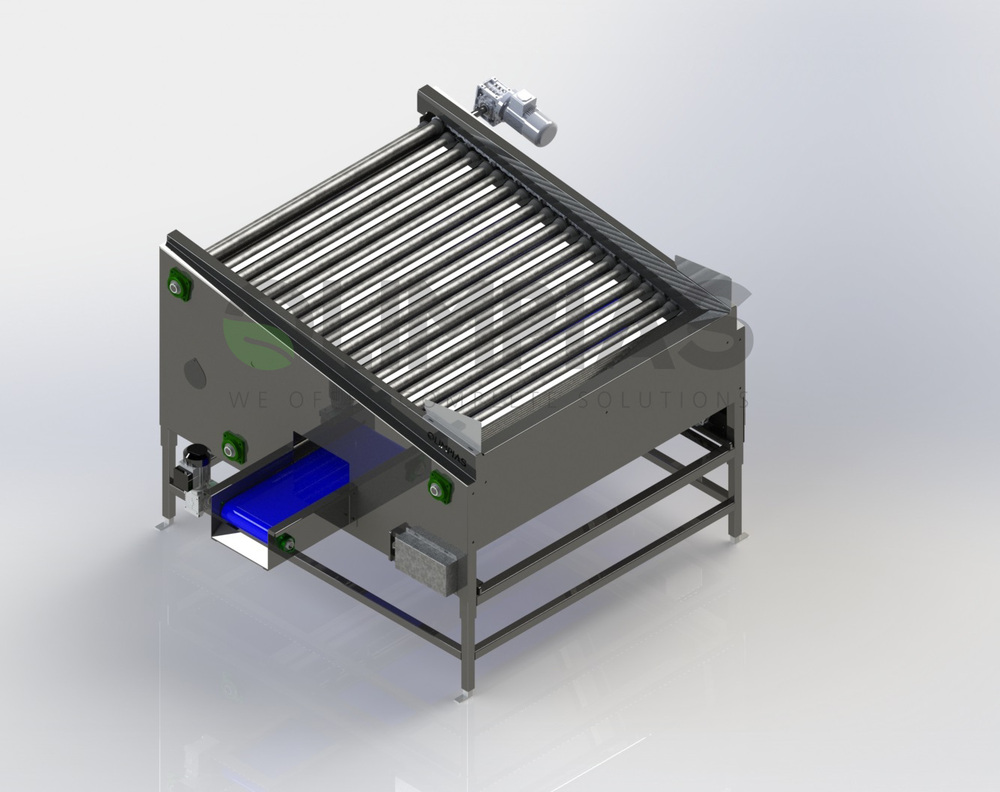

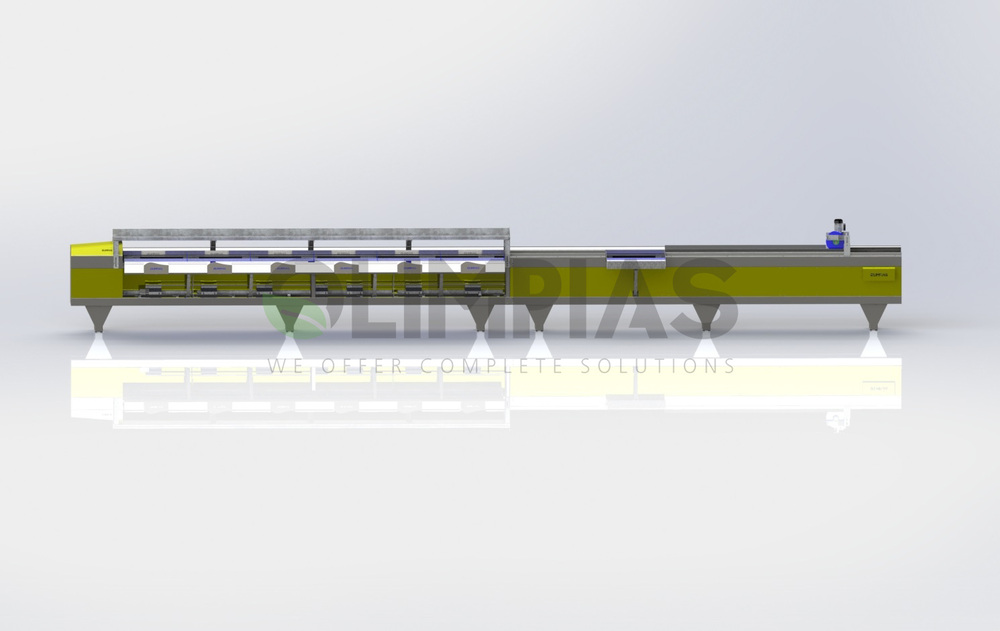

Mechanical Presizer

This machine is used to initialize fruits and vegetables such as potatoes, onions, carrots, and citrus fruits before further processing. It operates through double-cylinder arrays, which cover the entire width of the machine. In each array, the first cylinder is connected to a guided chain. The second cylinder is connected to the first with a metal frame. The distance between the cylinder arrays is mechanically adjusted, thus creating an opening.

between them, which allows the smaller-diameter products to pass through. These products are extracted from the machine through a conveyor belt located under the cylinders, while the rest remain on top of the cylinders to be transported to the end of the machine for further processing.

Construction data

- The machine's frame is made of sheet metal and beams, while the cylinders that contact the products are galvanized.

- Movement of the cylinders is actuated by a chain system located on each side. The chain system is held in place by a guide on each side. Power transmission is done by a suitable engine and inverter.

- The adjustment of the cylinder opening is achieved through manual handles located on the side of the machine.

- The PVC conveyor belt used to export smaller-diameter products is powered by a second motor included in the machine.

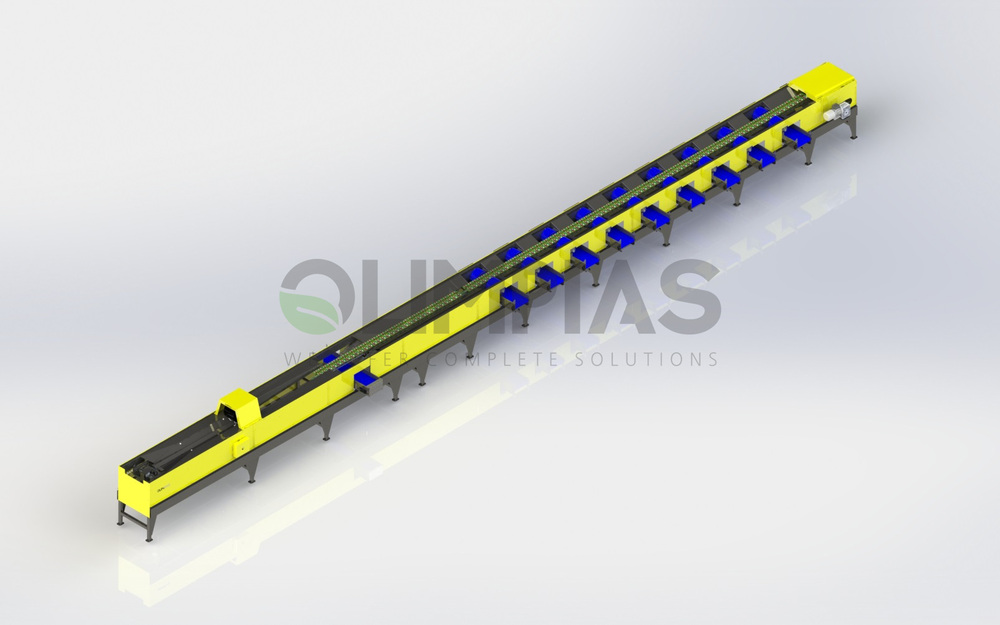

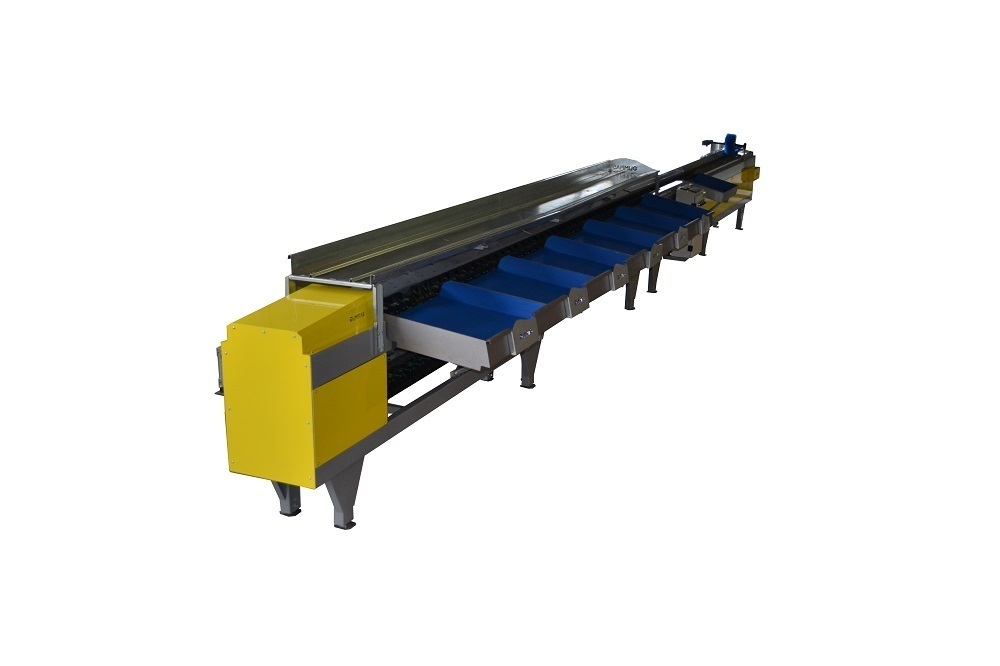

Mechanical Sizer of Side Emtying

The purpose of the machine is to sort the fruits based on their size. The machine is mainly used for the sorting of citrus fruits, being able to process even fruits with leaves. The machine consists of an inclined transportation belt carrying the fruits, and independent rotating drums (rollers). Each drum is calibrated through a steering wheel attached to it, increasing or decreasing the distance between the drum and the belt. Depending on the calibration of each drum, the fruits are forwarded to each fruit tray as long as their diameter allows them to pass through the opening that has been created.

The number of the packing stations varies depending on customer's needs. Each station contains a fruit tray measuring 1200 mm x 1000 mm, lined with elastic material to avoid any damage of the fruits while, above the unit’s entire length, a shelf is installed where the empty boxes are placed. Also, to make it easier for the operator to fill the boxes, a working bench is installed under the fruit trays, where the operator can place the empty box for packaging.

Electronic Graders

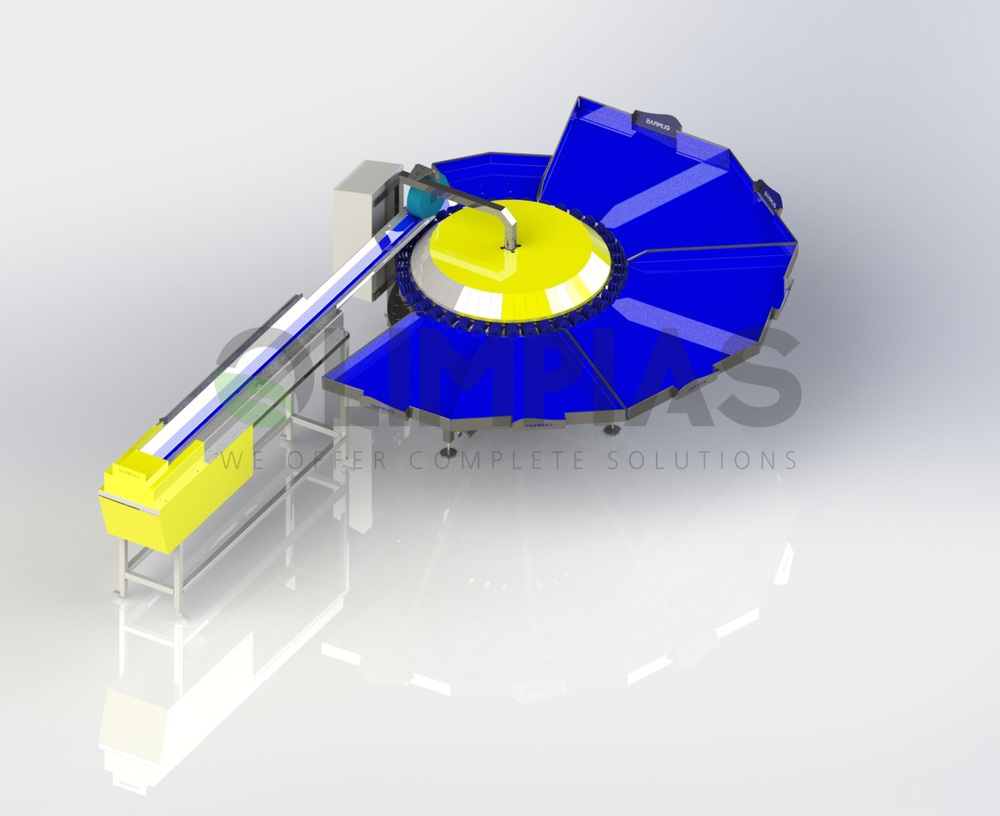

Mini CC round Sorter

The Mini-CC is a continuous-operating electronic sorter with many capabilities. Its flexibility and small size make it especially useful for small and bigger packaging facilities. The Mini-CC can easily process different types of fruits and vegetables with different diameters, measuring their weight with an electronic weighing device.

The Mini-CC can work as a stand-alone machine or as part of a more complex processing line.

The sorting machine is fully automated. The operator can set up and run the machine through a computer or a display panel.

The machine consists of:

- Main body with power unit.

- Weighing device.

- Product transportation system (rotating disk – fruit carriers).

- Fruit trays for the sorted fruits.

- Electronic sorting system by weight.

- Electrical panel with control display.

The Mini-CC can work as:

- An electronic sorter of continuous operation.

- A sampling machine.

- A semi-automatic batching-packaging machine with the addition of box filling and bagging machines.

Processing cycle:

- The fruits are transferred to the machine through its infeed V-belt.

- The V-belt places the incoming fruits in a row one after the other, ensuring the proper and continuous flow of products to the sorter.

- At the entry point, the products are placed in the cups passing through a soft brush system ensuring the safe placing of the fruits without damage.

- The cups carrying the fruits pass over the weighing system (load cell) so the electronic system can receive the weight of every fruit and sort it according to the program the operator has set.

- The ejection system on every exit gently tilts the cups so the fruits can exit the machine to the proper fruit tray for packaging.

Electronic Grader (OL_1LES)

The OL_1LES is a fully automated operation electronic sorter with one line. The machine can process many sensitive fruits and vegetables, such as apples, peaches, apricots, kiwis, tomatoes, citrus, pomegranates, avocado, and more, with diameters starting from 35mm. It offers wide flexibility as it can be constructed with different types of fruit carriers (cups) to fit the characteristics of each product. In its basic version it is equipped with an electronic sorting system for weight and 5+1 exits, but it can also be equipped with electronic sorting systems for diameter/volume, color, shape, external and internal quality, as well as with more exits.

The operator can set up and run the machine through a computer or a display panel. The transporting speed of the fruits is adjusted using a suitable Inverter. The capacity of the sorter reaches up to 8 fruits per second.

The machine consists of:

- Front side.

- Weighing sorting unit (color–diameter sorting unit with the use of a camera - optional).

- Back side (including power unit).

- Product transferring system (cups).

- Fruit trays (the number of fruit trays may vary depending on the processing needs).

Processing cycle:

- The fruits are transferred to the machine through its infeed V-belt.

- The V-belt places the incoming fruits in a row one after the other, ensuring the proper and continuous flow of products to the sorter.

- At the entry point, the products are placed in the cups passing through a soft brush system ensuring the safe placing of the fruits without damage.

- The cups carrying the fruits pass over the weighing system (load cell) so the electronic system can receive the weight of every fruit and sort it according to the program the operator has set.

- The ejection system on every exit gently tilts the cups so the fruits can exit the machine to the proper fruit tray for packaging.

The machine is constructed from a painted structural steel framework and plates, welded and/or bolted. The top cover of the sorter is made of INOX (AISI304). The stands are height adjustable.

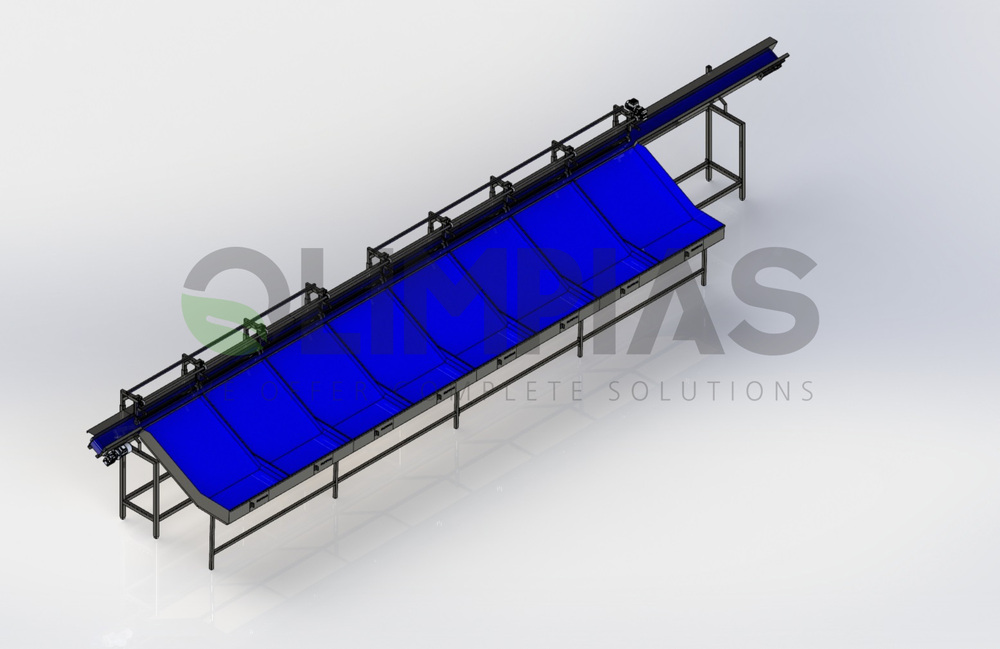

Electronic Grader (OL_2LES_FT)

The OL_2LES is a fully automated operation electronic sorter with one line. The machine can process many sensitive fruits and vegetables, such as apples, peaches, apricots, kiwis, tomato, citrus, pomegranates, avocado and more, with diameters starting from 35mm. It offers a wide flexibility as it can be constructed with different types of fruit carriers (cups) to fit the characteristics of each product. In its basic version it is equipped with an electronic sorting system for weight and 5+1 exits, but it can also be equipped with electronic sorting systems for diameter/volume, color, shape, external and internal quality, as well as with more exits.

The operator can set up and run the machine through a computer or a display panel. The transporting speed of the fruits is adjusted using a suitable Inverter. The capacity of the sorter reaches up to 16 fruits per second.

The machine consists of:

- Front side.

- Weighing sorting unit (colour – diameter sorting unit with the use of a camera - optional).

- Back side (including power unit).

- Product transferring system (cups).

- Fruit trays (the number of fruit trays may vary depending on the processing needs).

- Packing station (optional).

Processing cycle:

- The fruits are transferred to the machine through its infeed V-belt.

- The V-belt places the incoming fruits in a row one after the other, ensuring the proper and continuous flow of products to the sorter.

- On entry point, the products are placed in the cups passing through a soft brush system ensuring the safe placing of the fruits without damage.

- The two lines of cups carrying the fruits pass over the weighing system (load cell) so the electronic system can receive the weight of every fruit and sort it according to the program the operator has set.

- The ejection system on every exit gently tilts the cups so the fruits can exit the machine to the proper fruit tray for packaging.

If the packing station option is installed, the operator has at his/her disposal empty boxes which are situated on the slanted deck above each tray. After filling the box, the operator pushes the box towards the belt, which then transports it to the final packaging bench, located at the end of the line.

Electronic Grader (OL_2LES_CB)

The OL_2LES is a fully automated continuous operational electronic sorter with two lines. The machine can process many sensitive fruits and vegetables, such as apples, peaches, apricots, kiwis, tomatoes, citrus, pomegranates, avocados and more, with diameters starting from 35mm. It offers wide flexibility as it can be constructed with different types of fruit carriers (cups) to fit the characteristics of each product. In its basic version it is equipped with an electronic sorting system for weight and 5+1 exits, but it can also be equipped with electronic sorting systems for diameter/volume, color, shape, external and internal quality, as well as with more exits.

The operator can set-up and run the machine through a computer or a display panel. The transporting speed of the fruits is adjusted using a suitable Inverter. The capacity of the sorter reaches up to 16 fruits per second.

The machine consists of:

- Front side.

- Weighing sorting unit (colour – diameter sorting unit with the use of a camera - optional).

- Back side (including power unit).

- Product transferring system (cups).

- Fruit exit belt system (the number of belts may vary depending on the processing needs).

Processing cycle:

- The fruits are transferred to the machine through its infeed V-belt.

- The V-belt places the incoming fruits in a row one after the other, ensuring the proper and continuous flow of products to the sorter.

- On entry point, the products are placed on the two lines of cups which pass through a soft brush system ensuring the safe placing of the fruits without damage.

- The cups carrying the fruits pass over the weighing system (load cell) so the electronic system can receive the weight of every fruit and sort it according to the program the operator has set.

- The ejection system on every exit, gently tilts the cups so the fruits can exit the machine to the proper fruit tray for packaging.